EUROLAB Laboratory offers accredited immersion testing to depths exceeding 100 feet. Immersion test setups are usually test product specific and require the use of special pressure vessels. With multiple pressure vessels available, EUROLAB is able to offer immersion testing of various sized test items to virtually any depth.

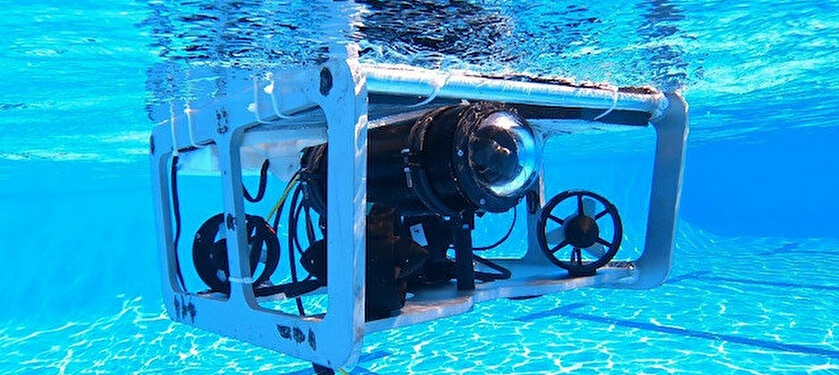

EUROLAB Immersion Test Laboratory Equipment

Our laboratory operates a variety of pressure vessels and associated support equipment. Our equipment can simulate depths over 100 feet. One of the immersion test tanks is 16 feet tall and has a three-foot radius.

Immersion Test Overview

To determine the sealing effectiveness of the component parts, a dip test is performed according to MIL-STD 202 Method 104. Immersion of the evaluated part in liquid at very different temperatures exposes it to thermal and mechanical stresses that will easily detect a faulty terminal assembly or a partially closed joint or molded housing. Such defects may result from faulty construction or from mechanical damage that may be produced during physical or environmental testing.

The water immersion test is usually performed immediately after such testing because it will tend to aggravate any newly discovered defects in gaskets, seams and bushings that might otherwise go unnoticed. This dip test is essentially a laboratory test condition and the procedure is designed as a measure of the seal's effectiveness following this test only. The choice of fresh or salt water as the test fluid depends on the nature of the component part being tested.

When electrical measurements are made after the water immersion test cycle to obtain evidence of leakage from the gaskets, using a salt solution instead of fresh water will facilitate the detection of moisture penetration. This test provides a simple and readily available way to detect the migration of fluids. Mentioned effects may include reduced insulation resistance, corrosion of internal parts, and the appearance of salt crystals. The described brine immersion test is not designed to be a thermal shock or corrosion test, but may incidentally reveal inadequacies in these respects.

Immersion testing is just one of the climate testing services we offer and our laboratory is equipped with the necessary equipment. EUROLAB is an immersion testing laboratory with significant experience. Contact us to determine how we can help you seal your enclosure by relying on our expertise in water immersion testing.

Immersion Test Standards

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.