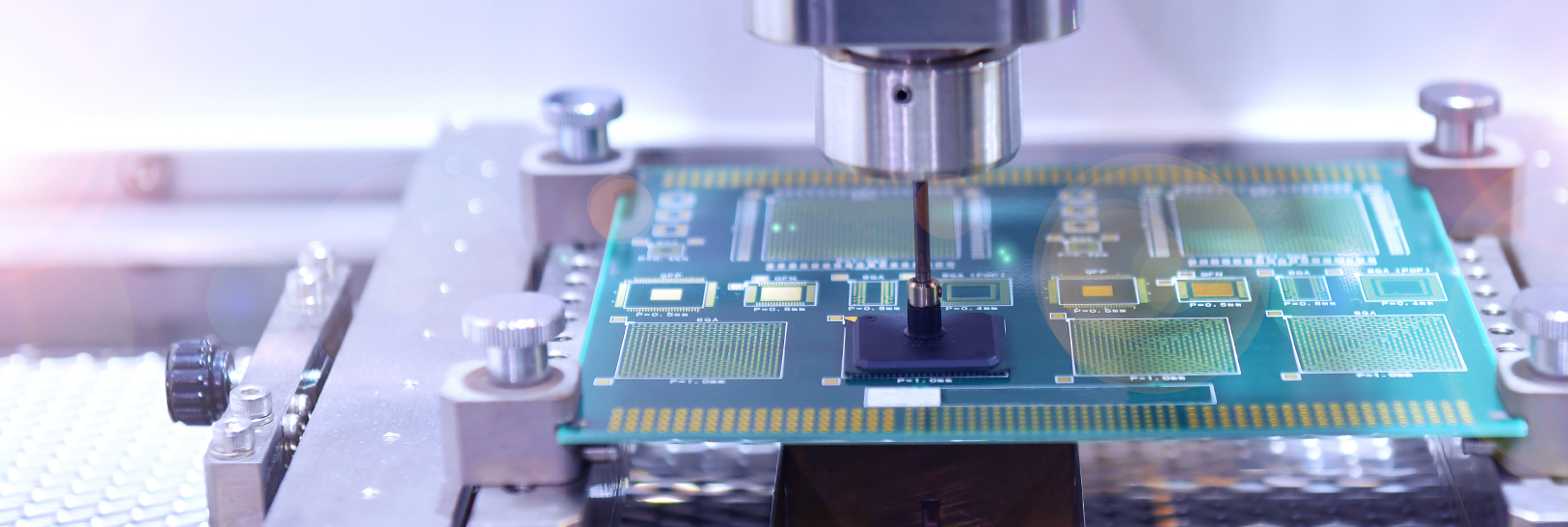

According to EUROLAB J-STD-001G, Aerospace and Military Applications Hardware Attachment provides testing and analysis services under Requirements for Soldered Electrical and Electronic Assemblies.

Standardization and quality control surrounding soldering and soldering applications for military electronics have been around for decades. Initially, the United States military, IPC J-STD-001 and IPC J-STD-001 and IPC J-STD-006. These standards seek to ensure that the final results of a soldering operation produce a reliable joint that can be audited and is guaranteed to meet minimum performance standards. This concept is essential for critical use cases such as coaxial cable assemblies for Hi-Rel applications and is part of creating MIL-DTL-17 assemblies.

If unsuitable solders or brazing practices are used, instead of forming a mechanically and electrically strong bond, a bond may form with various contaminants, unwanted intermetallic compounds and other defects. These defects can compromise the integrity of the solder joint, reduce reliable service life, increase insertion loss, and cause failures that are difficult to diagnose. Many defects that result from improper soldering and soldering practices are initially invisible and may require trained technicians familiar with standards and soldering to understand the problem.

IPC J-STD-001G

J-STD-001 is an industry standard guide for electrical and electronic assemblies detailing practices and requirements for solder joint manufacturing. Applications and requirements specified in J-STD-001 are divided into three classes based on the nature of their end use.

from J-STD-001F

CLASS 1 General Electronic Products

It includes products suitable for applications where the main requirement is the function of the completed assembly.

CLASS 2 Special Service Electronic Products

It includes products that require continuous performance and longevity, and where uninterrupted service is desired but not critical. Typically, the end-use environment does not cause malfunctions.

CLASS 3 High Performance Electronic Products

It includes products where sustained high performance or on-demand performance is critical, equipment downtime cannot be tolerated, the end-use environment may be unusually harsh, and equipment must operate as needed, such as life support or other critical systems.

EUROLAB Laboratory is ready to assist you with its expert testing team in military and defense industry products.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.