EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of MSFC-SPEC-164 testing. This standard specifies surface cleanliness requirements for oxygen, fuel and pneumatic components used in spacecraft fluid systems and associated ground support equipment (GSE) and test facilities.

This standard is not intended to specify cleanliness requirements for composite surfaces used in cryogenic service, but can be used to specify internal cleanliness requirements for metal-lined composite wrapped-over pressure vessels (COPVs). General cleaning requirements, verification procedures, drying and packaging requirements are provided. Every user will need low-level documentation to cover handling, system cleaning, solvent selection, cleaning verification, and maintenance. An engineering assessment will be required to determine the requirements for each system.

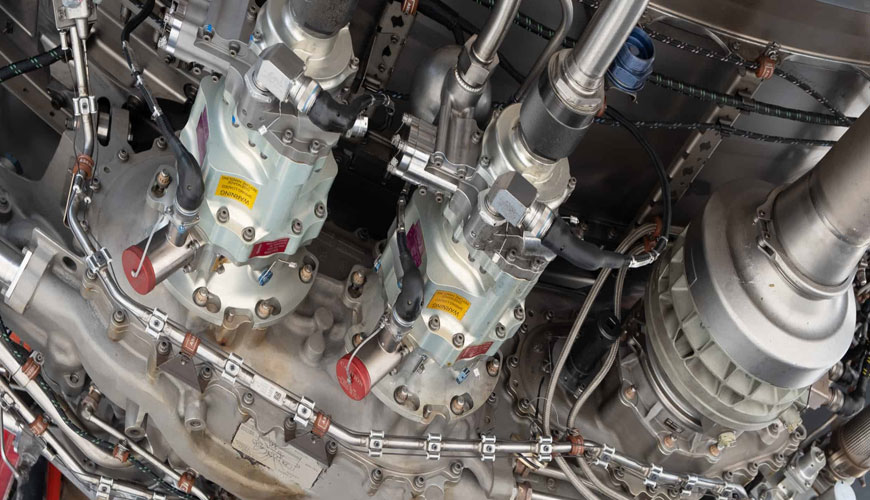

All parts, components, assemblies, systems or related equipment and associated GSE and test facility equipment for use on spacecraft shall be cleaned, inspected and packaged in accordance with this specification. Assembled parts that may be damaged during the cleaning process will be disassembled to allow cleaning. Designs for systems and system components should include, where practical, the ability to remove all valves and components from the system for precision cleaning.

All major surfaces of the system hardware must be pre-cleaned to remove dirt, sand, scale, corrosion, grease, oil and other foreign matter prior to any final fine cleaning. Metallic parts will be surface treated (cleaned, passivated or plated) as appropriate to prevent latent corrosion and contamination. Assembled parts unsuitable for this type of processing must be machined before assembly. Treated areas deteriorated during subsequent fabrication and assembly will be reworked as necessary to restore the original protective coating.

Important surfaces of previously cleaned system equipment should be visually free of dirt, sand, scale, corrosion, grease, oil and foreign objects before proceeding with any gentle cleaning. Scale-free discoloration due to welding or passivation is allowed.

EUROLAB assists manufacturers with MSFC-SPEC-164 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.