EUROLAB laboratory provides testing and compliance service within the scope of GMW 18388 standard. Evaluating the hole-expanding capacity of a plate is useful for evaluating and comparing its ability to form flanged holes, form tension flanges, resist edge cracking, and understand the general local formability properties of sheet metals.

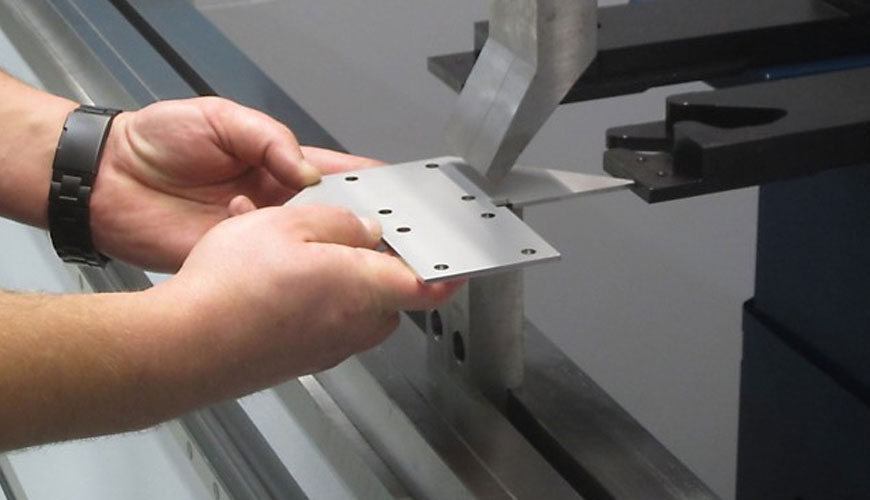

Various test methods are available to determine the suitability of the sheet for the respective forming operations. The hole tapping test is one of the best methods for assessing the suitability of sheet metal to form such "flanges" because it is very similar to the process used to create such flanges (plunge wheels) under manufacturing conditions, starting with punched holes.

The targeted light steel structure constantly uses stronger and thinner sheets as a result of economic and ecological conditions. At the same time, component geometries are becoming more complex. For this reason, the hole drilling test is increasingly used during the manufacture of car frame components to determine the ductility of edges on punched sheet metal as well as edge crack sensitivity.

One of the most widely used manufacturing processes in sheet metal working, cutting poses a challenge to the mechanical properties of the primary material. With shear cutting, the ductility of the newly formed edge can be significantly reduced compared to the base material. Due to this reduced ductility, edge crack initiation may occur during subsequent forming operations. During the forming process, the material is considered susceptible to edge cracking if it cracks almost exclusively from the sheet edge.

Because of the details given in this standard, the suitability of the test will be immediately apparent. Scattering in test results is minimized by adhering to the procedures specified in this standard.

EUROLAB assists manufacturers with GMW 18388 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.