The “SAE USCAR 45 Performance specification for welded wire-to-wire splices” standard developed by the Society of Automotive Engineers (SAE) describes test methods and performance requirements for ultrasonic welded wire-to-wire splices for automotive applications. Face-to-face, end-joint and center strip configurations can be tested with these test methods. The test methods described in this standard subject samples to stresses that simulate the lifetime exposure of a road vehicle. Stresses specified in this specification include thermal shock, temperature/humidity cycling and mechanical stresses from different directions.

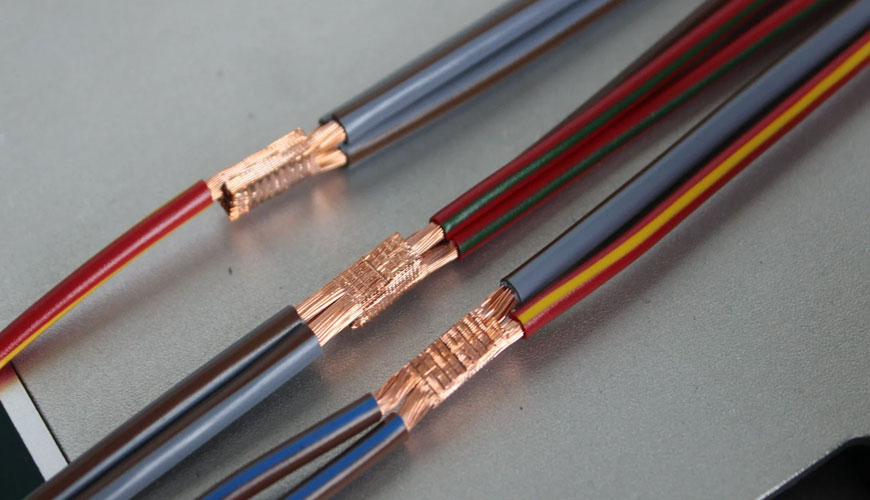

Cable or wire splicing is the process of joining the end points of two or more cable conductors. During the wire joining process, wires of different lengths are joined so that their original properties remain the same. Splicing can be done on electrical and fiber optic cables. Splicing is the joining of two or more conductors together to provide a permanent electrical termination and mechanical connection and is completed by crimping or soldering. The main purpose of splicing is to allow the joined wires to carry current. By splicing, it is possible to connect damaged cables instead of installing new cables. Splicing cables is a cheaper alternative than investing in new ones. The splice joint is used when the material being joined is not of the required length.

Wiring harness assembly manufacturers must strictly adhere to industry standards if the highest levels of quality are to be achieved and maintained. Current standards for ultrasonic cable splicing and termination have been developed globally by both original product manufacturers and their suppliers. One of the new standards that are becoming widely used is the SAE USCAR 45 standard for cable splicing and the SAE USCAR 38 standard for cable termination.

Today, best practice guidelines for ultrasonic welding are followed, initially during testing in the laboratory and finally in the manufacturing plant environment where process validation occurs.

However, splicing different cable sizes together is not recommended due to potential concerns about capacity, which could lead to current overload. The combined cables must have standard size and the same number of conductors. As a rule, the addition of wires does not lead to changes in voltage. For safety reasons, the power in the circuit is always turned off when adding cables. It is possible to safely splice three or more cables by following basic instructions.

Wire connection and wire-to-wire splicing are different processes. Wire bonding is the process of joining two wires or parts of a wire by intertwining wires in a certain way. A junction is made between two ends or between an end and the body of a wire. Wire-by-wire splicing is the process of joining with a joint or joints. So when two electrical wires are joined together, the resulting connection is normally called splicing. A good connection must not only be mechanically safe, but also create an electrical connection that is as effective a conductor as the wire itself. Wire-to-wire splicing is commonly used when wires are joined within an electrical outlet box or a junction box where wires come together in an electrical device. The splice is used wherever two lengths of wire are to be joined end to end. It is especially designed for jobs where there is a possibility of tension or tension being applied to the wires after the connection is made. To ensure good electrical contact at the connection point, the insulators of the cables must first be removed.

Among the numerous testing, measurement, analysis and evaluation studies it provides for businesses in various sectors, our organization also provides testing services in accordance with the SAE USCAR 45 standard, with a trained and expert staff and advanced technological equipment.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.