The following standards have been developed by Ford Motor Company in order to explain the properties that foam materials used in the production of vehicles should have:

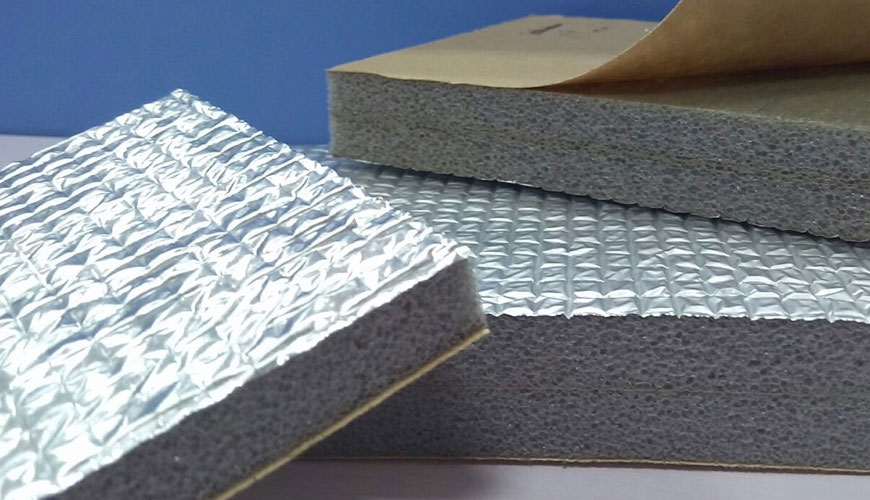

These standards describe minimum durability requirements for foams for general applications made from a variety of materials, including but not limited to polyurethane foam, polypropylene foam, and pressure-sensitive adhesive foam tape.

The materials defined in the WSS-M99P48-B1 standard are foam materials for interior, exterior, under-hood or underbody applications that are not covered by any other standard.

The materials defined in the WSS-M99P48-B3 standard are foam tapes for interior, exterior under-hood or under-body applications that are not covered by any other standard. Tape performance specifications for emblems, badges and body side moldings are outside the scope of this standard. These can also be foam pieces with a pressure-sensitive adhesive applied to one or both surfaces, coming from the same source as the materials defined in the WSS-M99P48-B1 standard. The pressure sensitive adhesive is tested on the intended substrate.

Polyurethane polyester foams are not durable when exposed to heat and light, so they should be used with caution in the production of vehicles. Additionally, within the scope of the WSS-M99P48-B3 standard, foam tapes do not contain biocides. If biocide is used in applications requiring biocide, for example in climate control, this should be stated.

These standards are performance-based and do not have validated sources.

Parts using this standard must meet the appropriate component performance specification. Headliner substrate or lamination, instrument panel, acoustic, thermal and energy absorbing foams, seat cushion or those whose performance is separately specified are outside the scope of the WSS-M99P48-B1 standard. In addition, emblems and badges and band performance for body side moldings or those where performance is specified separately are outside the scope of the WSS-M99P48-B3 standard. These issues are addressed in separate standards.

FORD WSS-M99P48-B1/B3 standards also include durability requirements and requirements for the characterization of production materials.

For example, the fogging test is subject to the standard "SAE J 1756-2006 Determination of fogging properties of automotive interior materials" and the tests require 100 hours of heating at 21 degrees, on a cooling plate at 3 degrees and 16 hours of post-test conditioning. The formation of a transparent film, droplets or crystals is a reason for rejection.

The flammability test is subject to the standards "ISO 3795 Road vehicles, tractors and machines for agriculture and forestry - Determination of the burning behavior of interior materials" and "SAE J 369-2013 Flammability of polymeric interior materials - Horizontal test method" and the maximum burning speed applied in the tests is 100 mm /minute.

In the mold resistance test, the sample is kept in a relative humidity environment of 98 percent plus/minus 2 percent and a temperature environment of 38 degrees plus/minus 2 degrees for 7 days. Sample size should be 100 x 100 plus/minus 2mm.

Adhesion strength testing is subject to “ASTM D1000-17 Standard test methods for pressure-sensitive adhesive coated tapes used in electrical and electronic applications” and must be capable of 180-degree peel, except when steel panels are replaced with the intended substrate. Tapes must meet the adhesion requirements specified in the standard unless otherwise specified by Ford Materials Engineering.

Substance restrictions imposed by subsequent legal regulations or FORD procedures apply to the materials covered in these standards. Restrictions are specified in the “WSS-M99P9999-A1 Restricted substance management” standard, which is updated every year.

Among the numerous testing, measurement, analysis and evaluation studies it provides for businesses in various sectors, our organization also provides testing services in accordance with "FORD WSS-M99P48-B1/B3 Foam performance" standards, with a trained and expert staff and advanced technological equipment.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.