EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and rapid testing services within the scope of USCAR 21 testing. The United States Automotive Research Council (USCAR) is an automotive research organization that aims to advance American automotive technology through combined research and development. This organization develops the common standards of the Society of Automotive Engineers (SAE).

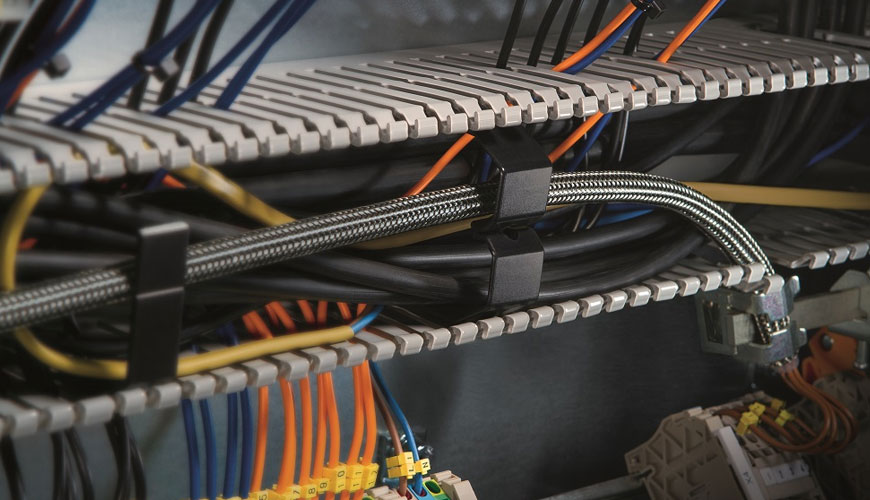

Developed by the Society of Automotive Engineers (SAE), the USCAR 21 standard defines test methods and requirements for verifying connections without solderless waves. The purpose of this test is to simulate the stress seen in the laboratory environment at a typical lifetime for a wave connection said to be 15 years and 150 miles, and to ensure that the wave is mechanically and electrically strong.

The interior of the USCAR 21 is designed for use using threaded automotive copper wire. However, when specifically mentioned, aluminum is also used in other structures or other basic materials such as cladding, steel core and the like. This standard does not apply only to unspecified wire types.

The USCAR 21 standard is based on the accepted environmental exposure level for automotive applications. In a planned vehicle application, if a product subject to this standard suffers from certain additional conditions, it must undergo special tests simulating the left possible real conditions, but be accepted for actual automatic application. For products certified by the supplier to comply with certain specifications of this standard, deviations must be documented and included in the test report.

Wave applications validated according to this standard are designed to replace wave information in replica components. The terminal supplier company is responsible for selecting and testing the set wave. Firms supplying the harness are responsible for the verification of all waves made according to this standard.

The environmental settings specified in this standard include thermal shock and temperature fluctuations and are used to force each production terminal and wire combination used in the test to simulate field exposure.

EUROLAB assists manufacturers with USCAR 21 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.