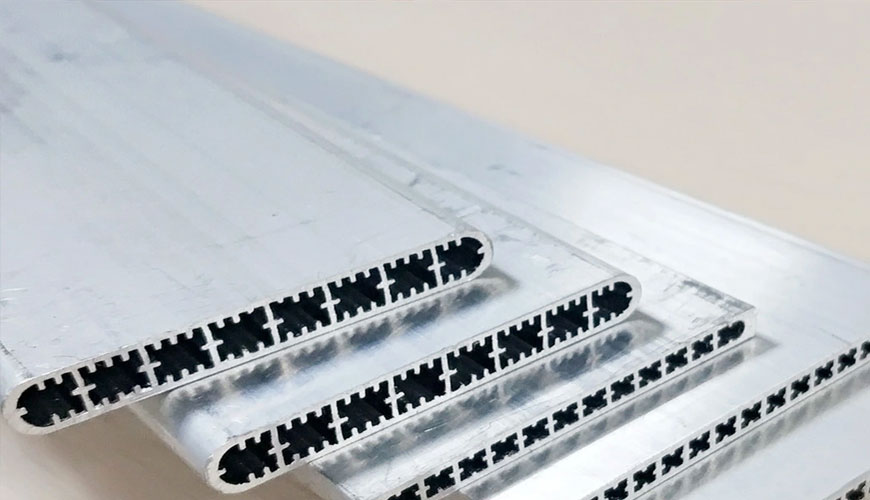

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of GMW 16153 testing. GMW 16153 contains procedures and guidelines for product testing of charge cooling channels.

Product Procedure:

Test procedure:

By subjecting charge air cooler ducts to rigorous product and testing procedures, manufacturers can ensure that they will operate reliably under a variety of conditions, improving the safety and longevity of the engine in which they are used.

EUROLAB assists manufacturers with GMW 16153 test compliance. Our test experts, with professional working mission and principles, offer you the best service and controlled testing process in our laboratories to our manufacturers and suppliers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.