MIL-STD-202 (F,G) testing establishes uniform methods for testing electronic and electrical component parts, including basic environmental testing and physical and electrical testing to determine resistance to the harmful effects of natural elements and conditions surrounding military operations.

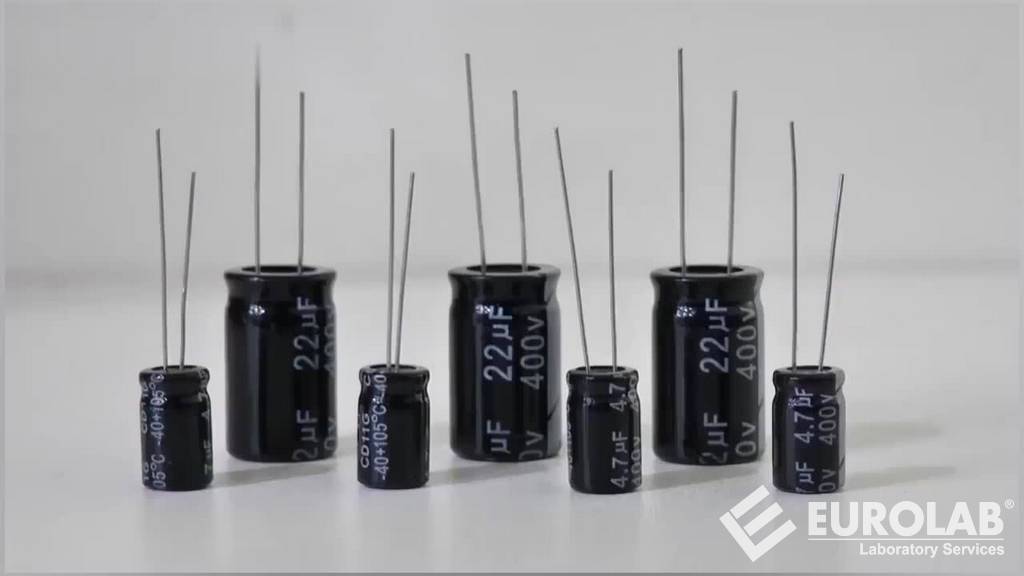

For the purpose of this standard, the term "component parts" includes items such as capacitors, resistors, switches, relays, transformers, inductors and others. This standard is intended to be applied only to small component parts weighing up to 300 pounds or having a root mean square test voltage of up to 50.000 volts, unless specifically stated otherwise.

The test methods described here are designed to serve several purposes:

MIL-STD-202 is one of the most important regulatory standards for defense contractors today. This document, which governs the testing protocol for all products and system components with printed circuit boards, sets out clear guidelines to follow if you want to bring your product to this lucrative market.

EUROLAB has an advanced network of laboratories to meet the testing needs of defense contractors and other customers. Our experienced in-house engineers provide assistance throughout all phases of the product development cycle, from assessing your legal requirements and determining the appropriate test sequence, to guiding you through compliance with both national and international standards.

MIL-STD-202 testing is a big component of what we do, and we strive to provide cost-effective solutions for every project.

EUROLAB can meet all required test methods for MIL-STD-202, especially the following:

EUROLAB, together with its state-of-the-art accredited laboratories and expert team, helps you get precise and fast results within the scope of MIL-STD-202 tests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.