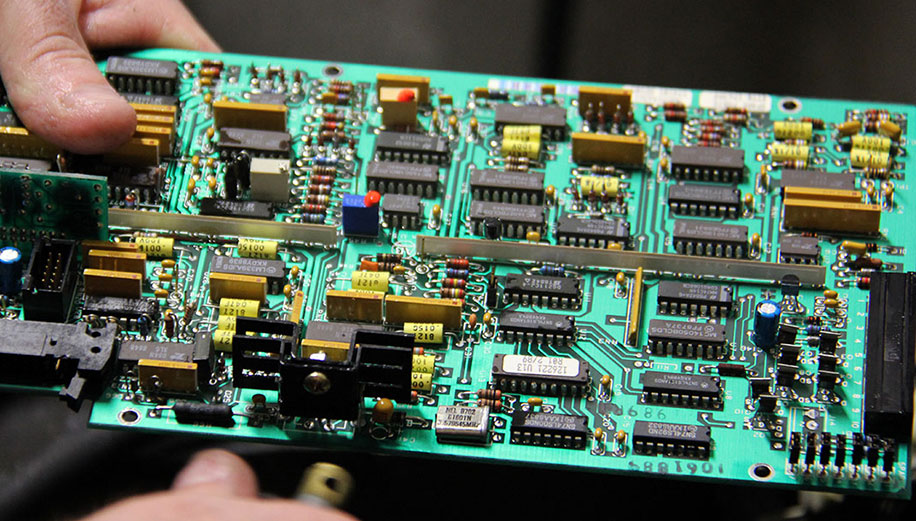

MIL-STD-202 is one of the most important legal standards for defense contractors today. By setting up the test protocol for all products and system components with printed circuit boards, it sets out clear guidelines to follow if you are going to put your product in this lucrative market.

EUROLAB has many years of experience in testing electronic components against military and other standards. We can help you meet your compliance requirements appropriately and on time.

The MIL-STD-202 standard “creates uniform methods for testing electronic and electrical component parts, including basic environmental tests and physical and electrical tests, to determine the resistance to the harmful effects of natural elements and conditions surrounding military operations.

For the purpose of this standard, the term "component parts" includes elements such as capacitors, resistors, switches, relays, transformers, inductors and others. Unless otherwise stated, this standard is intended to be applied to small component parts weighing only 300 pounds or with an average root test voltage of up to 50.000 volts. The test methods described here have been prepared to serve several purposes:

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.