Military standards developed by the U.S. Department of Defense are generally referred to in different ways:

Whichever way they are named, all these standards are known as the US defense standard. Standardization is useful in ensuring that materials and products used for military purposes meet certain requirements, partnership, reliability, compatibility with logistics systems, and similar objectives related to defense. In fact, these defense standards are used by other official institutions, technical organizations and businesses operating in various sectors besides the Ministry of Defense.

Although different names and different definitions are made, all of these documents are subject to the military standard general assessment, including defense features, manuals and standards. For example, military specifications (MIL-SPEC) define the physical and operational characteristics of a product. In contrast, military standards (MIL-STD) detail the processes and materials to be used in production.

In this context, document types are as follows:

The MIL-STD-810H Environmental Test Laboratory standard is designed as a defense standard among the document types described above. This standard regulates environmental engineering relations and laboratory tests to be applied within the framework of defense tests.

This standard, which was updated in 2019, emerged from the need to ensure appropriate performance, sustainability, repairability and logistical usefulness of military equipment, like other defense standards. Interchangeability and standardization were two very important factors in the design of these standards.

The biggest problem faced by the allied forces in the Second World War was the differences in the dimensional tolerances of the materials. There have been serious problems with American screws, bolts and nuts in fitting British equipment, and often these materials have not been used. In this regard, defense standards provide many benefits such as minimizing the number of ammunition types, ensuring the compatibility of the equipment and machinery used, and increasing the quality during the manufacture of military equipment.

The MIL-STD-810H standard prepared with these approaches covers the planning and engineering aspects of material acquisition processes, taking into account the effects of environmental conditions on these materials at all stages throughout the lifetime of military materials. This standard does not impose design or test specifications, but rather describes environmental compliance processes that result in test methods based on realistic material designs and material system performance requirements.

The MIL-STD-810H standard has been specially prepared for Ministry of Defense applications, but is still adaptable for commercial applications. The main objective of this standard is: to adapt the environmental design and test limits of a material to the conditions it will live for throughout its service life and to provide an explanation of how to apply it to environmental conditions throughout the material acquisition cycle, rather than creating laboratory test methods that strengthen the effects of the environments.

The latest update of the standard acknowledges that the environmental design and testing process has expanded to cover a wide range of administrative and technical interests. Accordingly, this update directs the environmental design and test direction to three main types of users, which are clearly different from each other, although they are closely related:

The first part of the MIL-STD-810H standard describes the management, engineering and technical roles in the environmental design and test adaptation process. It focuses on the process of adapting the material design and test criteria to the specific environmental conditions that a material will face during its service life.

The second part of the standard in question covers the environmental laboratory test methods to be applied according to the general and specific test adaptation guides described in the first section. Almost all of these methods are not routine applications that cannot be changed. It must be selected and adapted to produce the most suitable test data possible.

The third part of the standard was created by combining the following information and documents:

The third section provides planning and guidance for a realistic assessment of climatic conditions as a result of research, development, testing and evaluation of materials used throughout their life cycles in various climatic regions of the world. In this way, it is aimed to develop materials that will perform sufficiently under the environmental conditions likely to be found throughout its lifetime.

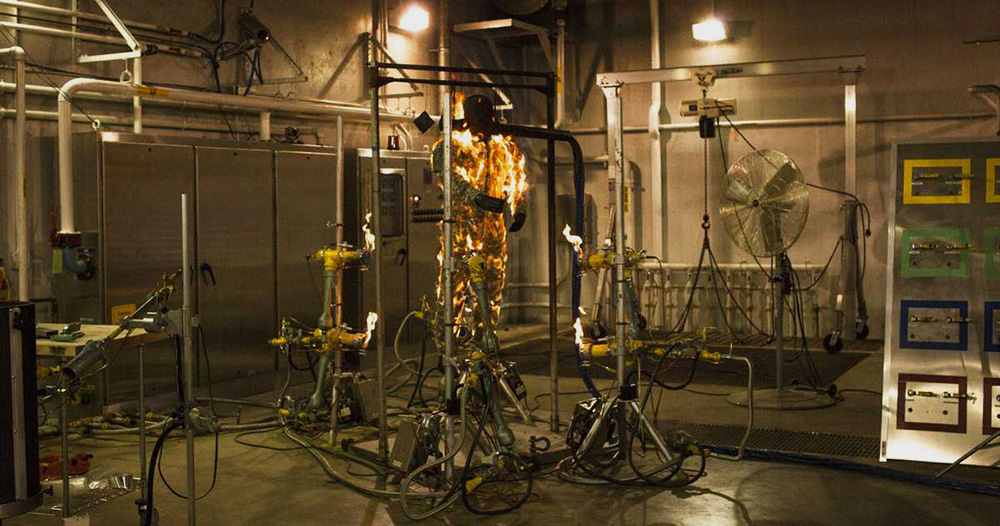

Environmental tests consisting of all mechanical, electrical and environmental stress factors affecting electronic equipment, cables and systems are carried out in advanced and accredited test laboratories in a fast, reliable and high quality. Environmental tests of military equipment and materials used for defense purposes are of particular importance.

The following tests are mainly carried out in environmental testing laboratories:

Our organization also provides MIL-STD-810H Environmental test laboratory services to businesses within the framework of laboratory testing services.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.