EUROLAB laboratory provides testing and compliance services within the scope of ASTM A370 standard. The ASTM A370 standard provides information on the strength and ductility of materials under uniaxial tensile stresses. From brittle wires to structural steel, lead and copper to aluminum, steel and titanium alloys, metal alloy manufacturers must test their products and materials to meet quality specifications and meet required industry standards.

Metal fabrication requires assurance that your incoming raw materials and outgoing product have the appropriate strength and ductility needed to produce products that meet competitive specifications. You need accurate, repeatable data you can trust for Ultimate Tensile Strength (UTS), Percent Elongation, Shear Yield Strength and Modulus of Elasticity (Young's Modulus). A robust, reliable, low-maintenance test system that consistently delivers the stress-strain tensile properties you need will go a long way in providing comfort and efficiency in your production processes.

ASTM A370 is a testing standard that covers mechanical testing definitions and procedures for steel products such as forged and cast steels, stainless steels, and related alloys. This standard covers tension, bending, hardness and impact tests. The various mechanical tests described in this specification can be used to determine the properties required in product specifications.

A370 differs from E8 in that it defines sample properties of steels specific to several different product types. These products discuss testing rod, tube, fittings, and round wire and are included in the appendices to ASTM A370 with some procedure descriptions. It is important to note that although the appended sections complement the general part of the standard, in case of conflict, the product standard usually applies.

When these test methods are referenced in a metric product specification, yield and shrinkage values can be determined in inch-pound (ksi) units and then converted to SI (MPa) units. Elongation determined at 2 or 8 inch inch-pound gauge lengths may be reported in SI gauge lengths of 50 or 200 mm, respectively, as appropriate.

Conversely, when referring to these test methods in a pound-to-inch product specification, yield and strain values can be determined in SI units and then converted to inch-pound units. Elongation determined at SI gauge lengths of 50 or 200 mm may be reported in 2 or 8 inch inch-pound gauge lengths, respectively, as appropriate.

This standard does not purport to address all, if any, safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and to determine the applicability of regulatory restrictions prior to use.

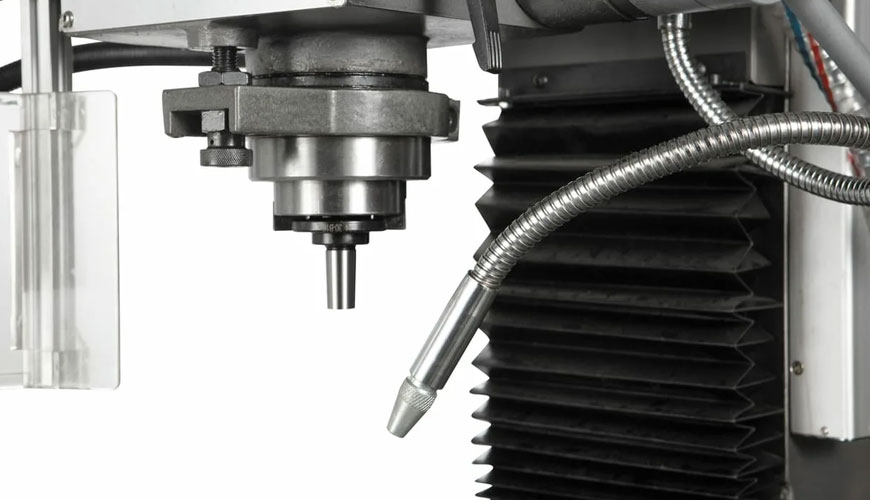

Our company, EUROLAB, provides mechanical testing services of steel products within the framework of national and international standards, with its trained and expert staff and advanced technological equipment, among numerous test, measurement, analysis and evaluation studies. Provides testing services within the scope of ASTM A370 standard.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.