The ASTM D1238 test covers the determination of the extrusion rate of molten thermoplastic resins using an extrusion plastometer. After a certain preheating time, the resin is extruded from a die with a certain length and hole diameter under the conditions of temperature, load and piston position stipulated in the barrel. Four procedures have been described.

Procedure A is used to determine the melt flow rate (MFR) of a thermoplastic material. Units of measure are grams of material/10 minutes (g/10 minutes). It is based on the measurement of the mass of material extruded from the die over a given period of time. It is generally used for materials with melt flow rates that fall between 0,15 and 50 g/10 min.

Procedure B is an automatically timed measurement used to determine the melt flow rate (MFR) and melt volume rate (MVR) of thermoplastic materials. MFR measurements made with Procedure B are reported in g/10 min. MVR measurements are reported in cubic centimeters/ten minutes (cm3/10 minutes). Procedure B measurements are based on determining the volume of material extruded from the die over a given period of time. The volume is converted into a mass measurement, where the result is multiplied by the melt density value of the material. Procedure B is generally used with materials with melt flow rates between 0,50 and 1500 g/10 min.

Procedure C is an automatically timed measurement used to determine the melt flow rate (MFR) of polyolefin materials. It is often used as an alternative to Procedure B for samples with melt flow rates greater than 75 g/10 min. The test procedure is similar to Procedure B, except that the results obtained with Procedure C will not be assumed to be half the results produced by Procedure B.

Procedure D is a very weighted test, often referred to as the "Flow Rate Ratio" (FRR) test. Procedure D is designed to allow MFR determinations to be made using two or three different test loads (increase or decrease the load during testing) on a material load. FRR is a dimensionless number obtained by dividing MFR at higher test load by MFR at lower test load. Results from multi-weighted tests cannot be directly compared with results from Procedure A or Procedure B.

Polymers with melt flow rates less than 0,15 or greater than 900 g/10 min can be tested by the procedures in this test method; however, sensitive data has not been developed. The melt density is the density of the material in the molten state. It should not be confused with the standard density value of the material.

This standard is not intended to address security concerns (if any) associated with its use. It is the responsibility of the user of this standard to determine appropriate safety and health practices prior to use and to determine the applicability of regulatory restrictions.

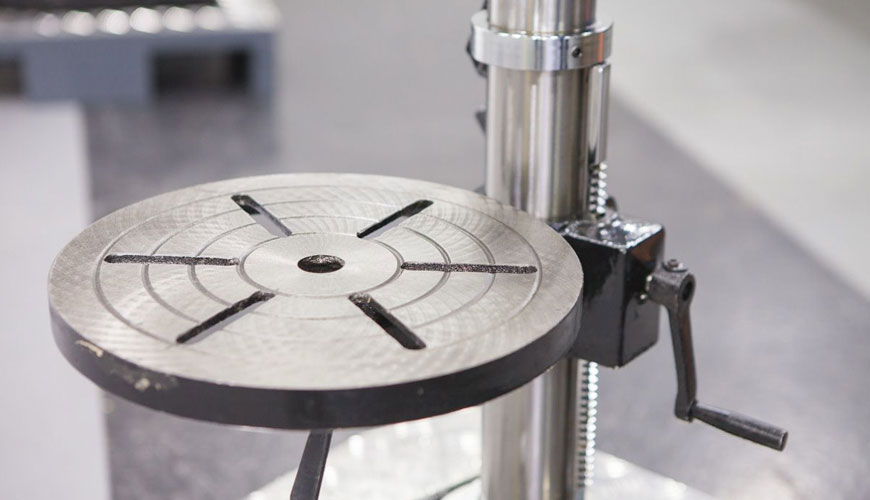

Our organization also provides testing services to businesses within the framework of laboratory testing services within the scope of ASTM D1238 Extrusion Plastometer and Standard Test Method for Melt Flow Rates of Thermoplastics.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.