EUROLAB laboratory provides testing and compliance services within the scope of ASTM F1249 standard. The ASTM F1249 standard covers a procedure for determining the rate of water vapor transmission through flexible barrier materials. The method is applicable to sheets and films up to 3 mm (0,1 inch) thick, consisting of single or multi-layer synthetic or natural polymers and foils, including coated materials.

It provides the determination of the water vapor permeability rate (WVTR), the permeability of the film to water vapor and the water vapor permeability coefficient for homogeneous materials. Water vapor permeability and water vapor permeability values should be used carefully. The inverse relationship of WVTR to thickness and direct relationship of WVTR to partial pressure difference of water vapor may not always hold.

Water vapor transfer rate (WVTR) or moisture vapor transfer rate (MVTR) is a method used to measure the passage of water through a material. Using ASTM F1249, this analysis tool helps to calculate or measure the permeability of vapor barriers.

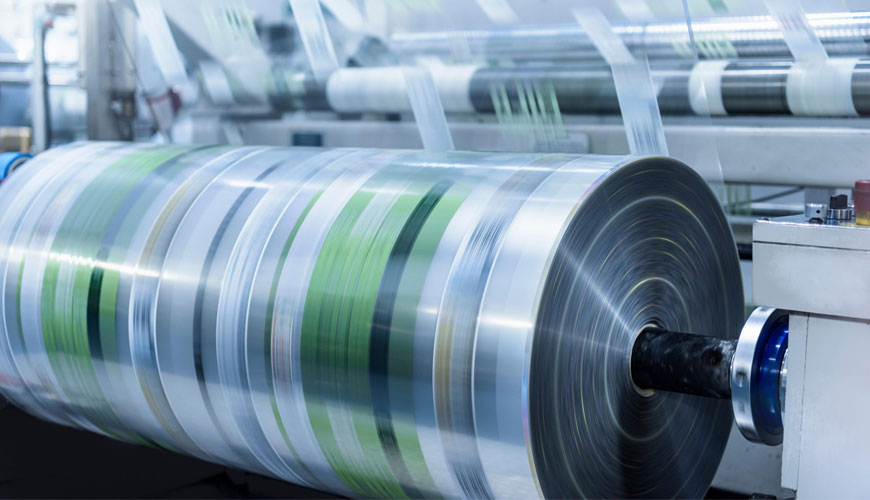

In packaging or other industrial applications, finding the vapor transmission rate through flexible materials is crucial. The main important factors involved in material permeability are the thickness of the material and environmental factors such as temperature, relative humidity. Reliable values for WVTR of plastic film and coating are determined by this test.

ASTM F1249 Test Procedure

Distilled water is filled into a glass and a small air gap is maintained between the sample and the water. The container is then sealed, except for the test sample, to prevent vapor loss. The instrument is weighed first, then at regular intervals before the effects become linear. The experiment should be carefully monitored to ensure that all weight loss is due to water vapor passing through the sample.

This standard does not purport to address all, if any, safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory restrictions prior to use.

Our organization, EUROLAB, provides standard test method services for water vapor transmission rate from plastic film and coating, using a modulated infrared sensor, within the framework of national and international standards, with its trained and expert staff and advanced technological equipment, among numerous test, measurement, analysis and evaluation studies. Provides testing services within the scope of ASTM F1249 standard.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.