The ASTM D638 Plastic Tensile Properties Test measures the force required to break a plastic specimen specimen and how far the specimen stretches or elongates to that breaking point.

In the ASTM D638 tensile test, the basic mechanical properties of the molding material are determined. These characteristic values are mostly used for comparison purposes.

The characteristic values are:

The ASTM D638 test method is designed to determine the tensile properties of plastic materials. And it can be used to test materials of any thickness up to 14 mm (0,55 inch). However, for thin sheet samples, including films smaller than 1.0 mm (0.04 inch), it is preferred to use ASTM Test Methods D882. All materials with a thickness of more than 14 mm [0.55in.] Must be shrunk by machining to apply this method.

Both ISO 527-1/-2 and ASTM D638 define test methods for tensile tests. The two standards are technically equivalent, but do not provide fully comparable results because sample shapes, test speeds, and method of result determination differ in some respects.

In the standard tensile test, results are based on a defined sample tensile velocity on the sample. However, loads on a component or structure in actual service can be over a wide range of deformation rates. Due to the viscoelastic properties of polymers, mechanical properties different from those measured in a standardized test specimen normally result under varying strain rates. Therefore, characteristic values determined in a tensile test are of only limited relevance for component design, but provide a very reliable basis for material comparisons.

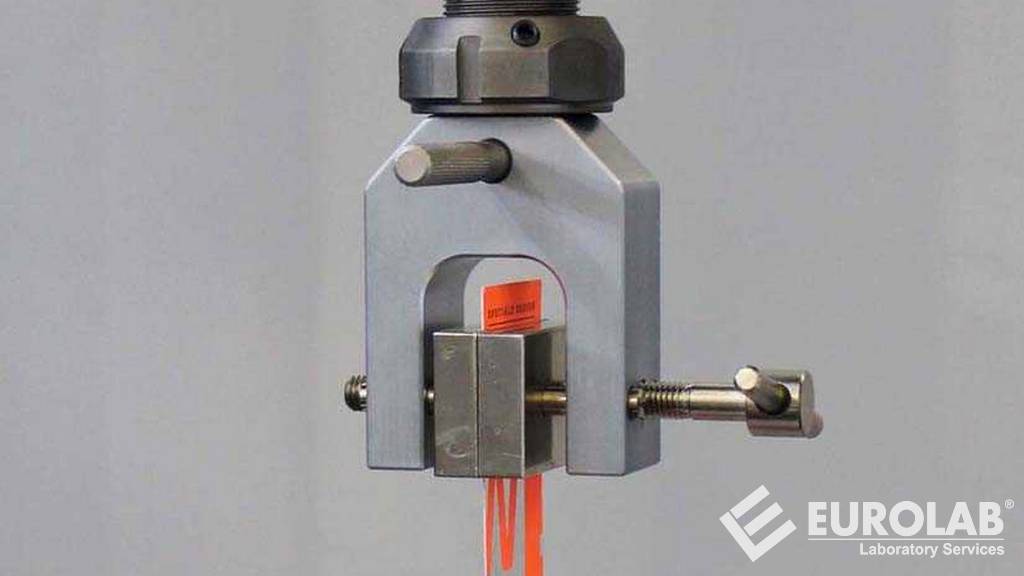

According to the ASTM D-638 tensile test procedure, samples are placed on the universal tester's handles at a certain holding distance and pulled until they fail. The test rate for ASTM D 638 is determined by the material specification. An extensometer is used to determine the elongation and tensile modulus.

A thermal chamber is integrated into the universal testing machine according to the Elevated or Reduced temperature test procedure. The chamber is designed to allow test connections from the base and crosshead of the universal tester to pass above and below the chamber. Standard test fixtures are installed inside the chamber and the test is performed in a controlled thermal environment as at ambient temperature. The chamber has built-in electric heaters for high temperatures and uses external carbon dioxide gas as a coolant for low temperatures. The size of the chamber places a limit on the maximum elongation achievable, and extensometers are usually not more than 200°C.

The following calculations can be made with the ASTM D638 test:

EUROLAB, together with its state-of-the-art accredited laboratories and expert team, helps you get precise and fast results within the scope of ASTM D638 test.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.