EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of ASTM D6109 testing. This standard is suitable for determining the bending properties of a solid or hollow plastic lumber product of square, rectangular, round or other geometric cross-section that exhibits viscoelastic behavior.

Test specimens are "as manufactured" parts with no modifications or machining of surfaces beyond cutting to length. As such, it is not a material property test method, but a test method for evaluating the properties of plastic timber as a product. Bending strength cannot be determined for products that do not break or break in excess outer fiber.

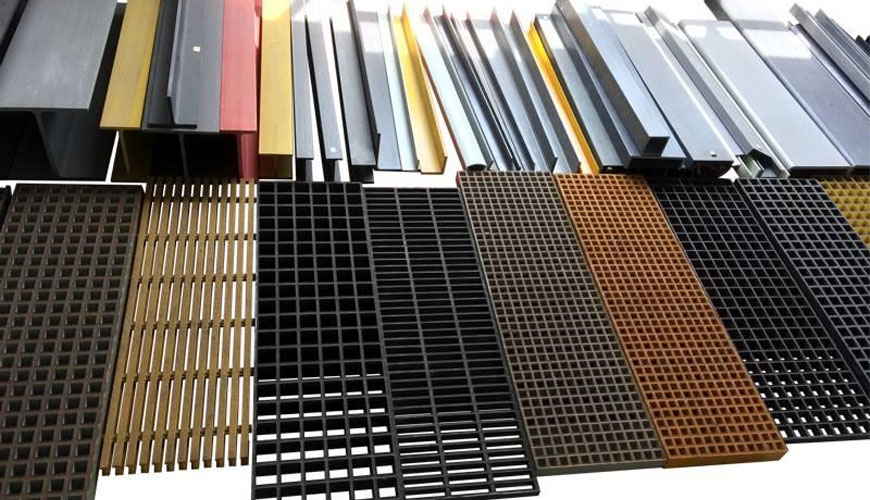

Plastic lumber is currently produced using several different plastic manufacturing processes. These processes use a variety of plastic resin material systems that include fillers, fiber reinforcements and other chemical additives. The test methods can be applied to plastic timber products where the plastic resin is the continuous phase, regardless of the manufacturing process, the type or weight percent of plastic resin used, the type or weight percent of fillers used, the type or weight percent of reinforcements used. type or weight percent of other chemical additives.

As an alternative to a single resin material system, various and multiple combinations of both raw and recycled thermoplastic material systems are permitted in the manufacture of plastic lumber products.

Different types and combinations of inorganic and organic filler systems are allowed in the manufacture of plastic timber products. Inorganic fillers include materials such as talc, mica, silica, wollastonite, calcium carbonate, and the like. Organic fillers include lignocellulosic materials made or derived from wood, wood flour, flax husk, rice hulls, wheat straw and combinations thereof.

Fiber reinforcements used in plastic lumber include manufactured materials such as fiberglass (chopped or continuous), carbon, aramid and other polymers; or lignocellulosic based fibers such as flax, jute, kenaf and hemp.

A wide variety of chemical additives are added to plastic lumber formulations to serve many different purposes. Examples include colorants, chemical foaming agents, ultraviolet stabilizers, flame retardants, lubricants, antistatic products, biocides, heat stabilizers and coupling agents.

EUROLAB assists manufacturers with ASTM D6109 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.