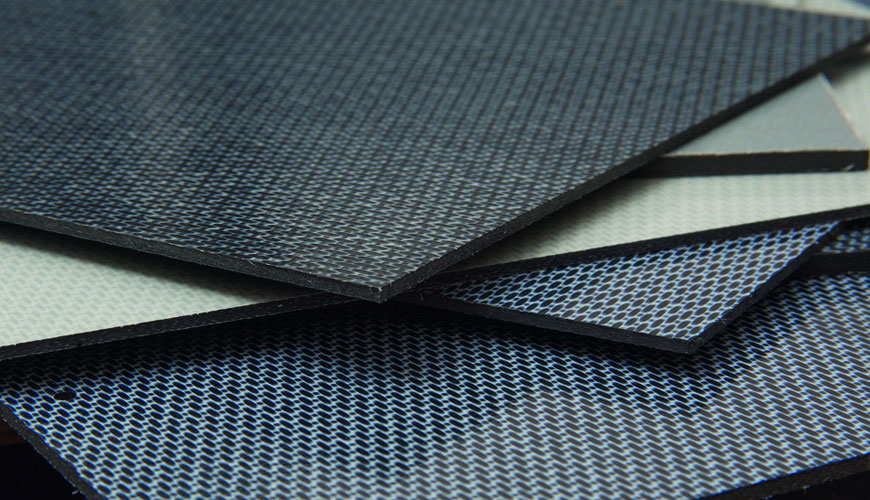

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of ASTM D7136 testing. This standard specifies the damage resistance of composite laminated plates with a versatile polymer matrix subjected to a weight-drop impact event.

Composite material forms are limited to continuous fiber-reinforced polymer matrix composites by the range of test laminates and thicknesses. Instructions for modifying these procedures for determining the damage-resistance properties of sandwich structures are provided in Application D7766.

A flat, rectangular composite plate is subjected to an out-of-plane, concentrated impact using a hemispherical impactor weight-drop device. The potential energy of the drop weight is specified prior to testing, as defined by the impactor's mass and the drop height. Equipment and procedures are provided for optional measurement of contact force and velocity during an impact event. Damage resistance is measured in terms of the size and type of damage that occurs in the sample.

The test method can be used to screen materials for damage resistance or to damage a sample for subsequent damage tolerance testing. When the embedded plate is tested according to Test Method D7137/D7137M, the overall test sequence is often referred to as the Post Impact Compression (CAI) method. According to Test Method D6264/D6264M, quasi-static indentation can be used as an alternative method to measure damage resistance properties and to generate damage from an out-of-plane force.

The damage resistance properties produced by this test method are highly dependent on a variety of factors including specimen geometry, placement, impact geometry, impactor mass, impact force, impact energy, and boundary conditions. Therefore, results are often not scalable to other configurations and are specific to the combination of geometric and physical conditions being tested.

Values stated in SI units or inch-pound units will be considered standard separately. The values specified in each system may not be exactly equivalent; therefore, each system should be used independently of the other. Combining values from the two systems may result in non-compliance with the standard.

This standard does not purport to address all safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices prior to use and to determine the applicability of regulatory restrictions.

EUROLAB assists manufacturers with ASTM D7136 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.