The scope of the ASTM D951 shipping container test is to determine how well a container resists water. This standard can also be used to assess the ability of a container to withstand water deterioration.

This particular packaging test is just one of several shipping container tests. It is typically combined with other tests such as drop test, inclined impact test, vibration test and compression test. The overall aim is to ensure that the contents of the shipping container effectively protect its content during transportation difficulties.

The test requires at least three cups. Containers should be closed and sealed as usual. The containers should also be similar to the actual containers to be used. The standard does not allow the "gold unit" to be tested. Some tests will require emptying of shipping containers. Other tests will require the containers to have the content they prepared for dispatch.

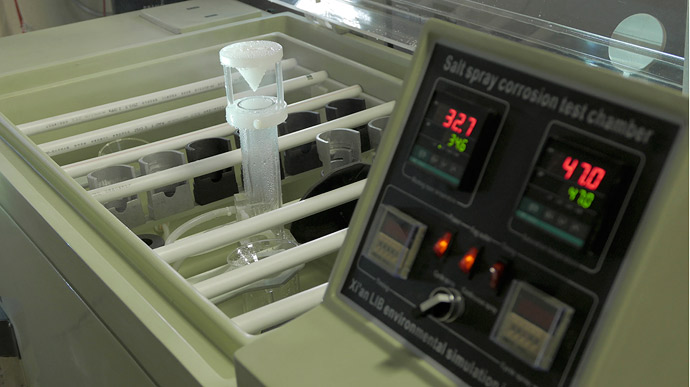

ASTMD 951 package testTo complete the test laboratory must have the following equipment and features. These features are:

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.