EUROLAB laboratory provides testing and compliance services within the scope of ASTM E209 standard. The ASTM E209 standard covers the compression test in which the specimen is heated to a constant and uniform temperature and held at the temperature at which an axial force is applied at a controlled strain rate.

For metals with an extremely high proportional limit or low modulus of elasticity, 0,2% total strain under load can be achieved before the 1.5% offset yield strength is reached. In this case, the end point of the test may be reported as 0,2 percent offset yield strength unless rupture occurs before this point.

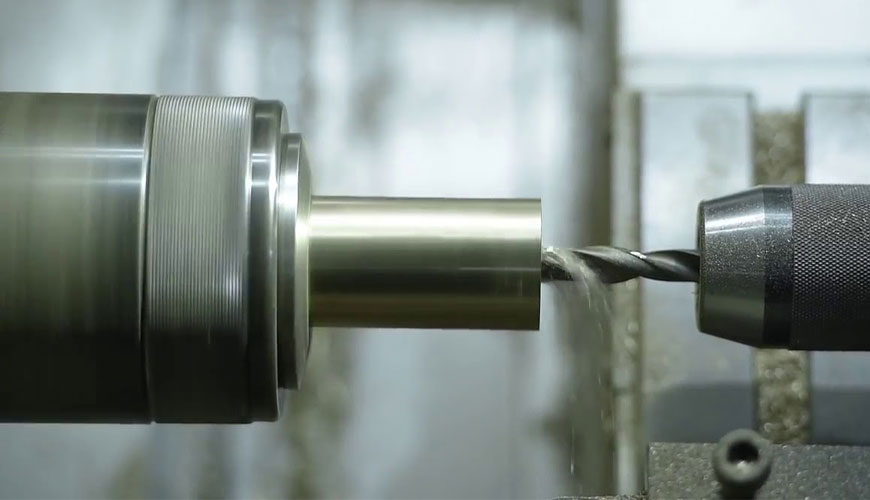

For acceptable compression tests, it is imperative that the specimens are not bent before the endpoint is reached. Therefore, equipment and procedures shall be designed to ensure uniform loading and axial alignment. Preferred test conditions are recommended so that data from different sources running tests are comparable.

Data from the compression test may include yield strength, yield point, Young's modulus, stress-strain curve, and compressive strength (see Terminology E6). In the case of a material that does not fail in compression due to fracturing fracture, the compressive strength is a value dependent on the total strain and the specimen geometry.

Compressive properties are of interest in the analysis of structures subjected to compressive or bending loads or both, and in the analysis of metalworking and manufacturing processes involving large compressive deformation such as forging and rolling. For brittle or non-ductile metals that fracture in stress at stresses below the yield strength, compression tests offer the possibility to extend the strain range of stress-strain data. While the compression test is not complicated by necking as is the tensile test for certain metallic materials, buckling and rolling can complicate the results and should be minimized.

This application covers compression testing in which the specimen is heated to a constant and uniform temperature and held at the temperature at which an axial force is applied at a controlled strain rate. The machines used for the compression test must comply with the specified conditions. The apparatus and method for heating the samples are not specified. The procedure for temperature control, temperature measurement, strain rate during testing and strain measurement is presented in detail. The complete compression test system consisting of jigs, strain gauges and recorders must be qualified in accordance with specified requirements.

Values stated in inch-pound units should be considered standard. Values in parentheses are mathematical conversions to non-standard SI units, provided for informational purposes only.

This standard does not purport to address all, if any, safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and to determine the applicability of regulatory restrictions prior to use.

Our organization, EUROLAB, provides compression tests of metallic materials at high temperatures with conventional or fast heating rates and strain rates, within the framework of national and international standards, with its trained and expert staff and advanced technological equipment, among numerous test, measurement, analysis and evaluation studies. Provides testing services within the scope of ASTM E209 standard.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.