The purpose of ASTM F2054 is to determine the minimum burst strength of a seal. The seal is around a flexible package that is internally pressurized and sealed. This bursting test will increase the pressure of the packaging until the gasket bursts.

Retaining plates help stabilize the product and distribute pressure evenly. The uniform pressure distribution will help identify the weakest point in the gasket. This procedure applies to flexible packages with gasket around the perimeter (bags). It also applies to bags with peelable sealing feature.

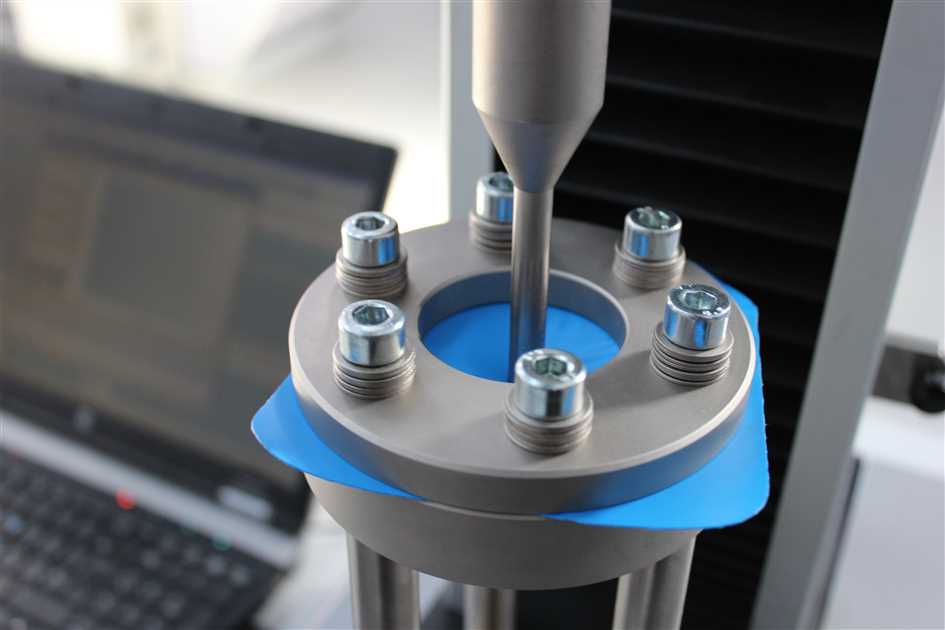

Packages are tested in an apparatus that applies pressure internally until the gasket breaks (bursts). The package is placed between two holding plates, which add rigidity to the package, between the holding plates. This prevents the package from expanding but releases the seal edge. An internal sensor will monitor the pressure as it increases during the test. There are two configurations available for this test method, depending on the application:

This test showed sealing error trends when the packaging was exposed to different pressures. Pressure differences are common in the field during sterilization and transportation. It is important to note that the purpose of this test is for the bursting strength of the gasket. The test cannot determine the overall strength of the pack or the regions of the pack that come into contact with the limiting plates. It can be used to assess sealing strength at testing, manufacturing and various distribution points.

For this test, the packaging is closed on three sides, and one side remains unsealed. It is placed in the test apparatus and then the open side is closed by a clamping mechanism. The pressure test nozzle is placed on the open end of the package before it is clamped. Test the appropriate number of samples to accurately determine representative performance.

The package must be conditioned for at least 72 hours before starting the test. It is best to perform the test in a conditioned environment. However, if this is not possible, the report should indicate the conditions during the test. It is recommended to mark all sample packs so that they are positioned identically for consistent testing. Start inflating the package by increasing the internal pressure until the package bursts due to pressure.

For this test, the packaging is sealed on all four sides and placed between the anchor plates. The pressurizing nozzle is inserted through a hole in the body of the package, but it should have an airtight seal around the nozzle. Test the appropriate number of samples to accurately determine representative performance.

The package must be conditioned for at least 72 hours before starting the test. It is best to perform the test in a conditioned environment. However, if this is not possible, the report should indicate the conditions during the test. Start inflating the pack by increasing the internal pressure until the pack explodes due to pressure.

Packages should be examined to determine where the rupture occurred. If the rupture occurs outside of the seal, the test sample may be invalid.

The testing laboratory will write a comprehensive report provided by ASTM F2054.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.