EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 60068-2-44 testing. Provides background information and recommendations for specification authors, including references IEC EN 60068-2-20, IEC EN 60068-2-54, and IEC EN 60068-2-58.

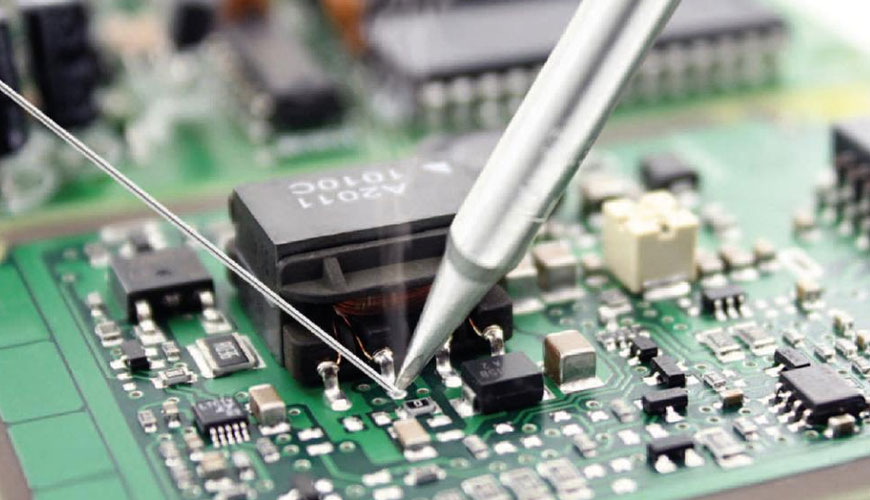

It is not enough for an electronic component to have tips suitable for soldering (which can be wetted by molten solder). For batch soldering operations, it must meet three other requirements:

Therefore, some electronic components that contain lubricated mechanical parts (e.g. switches) or that are open-sealed are susceptible to contamination (e.g. relays, potentiometers) or contain a plastic material with poor heat resistance (e.g. certain capacitors with thermoplastic dielectrics).

For these reasons, a careful distinction must be made between the solderability of the component, which refers to the overall suitability for industrial soldering, and the wettability of the termination, which refers only to the ease of coating the termination with solder.

The purpose of the tests is to bring the component and solder together under controlled conditions so that the wetting quality can be evaluated according to defined criteria. Basically, soldering time tests are an estimate of the time it takes for the contact angle to fall evenly to a low angle at all points in the solder boundary. In some tests, this is evaluated only by visual inspection. In others, time is measured. Purely quantitative tests are tests in which both time and the force exerted on the sample by the surface tension of the solder are measured.

EUROLAB assists manufacturers with IEC EN 60068-2-44 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.