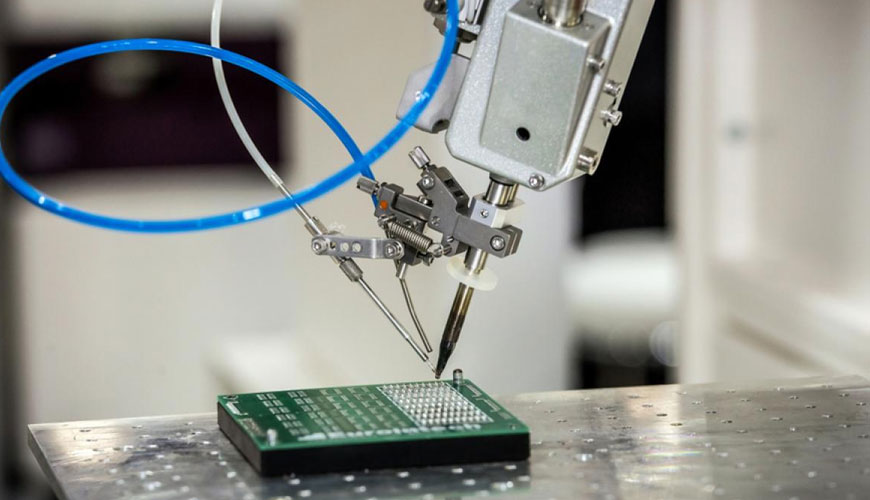

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 60068-2-20 test. IEC EN 60068-2-20 summarizes the Ta and Tb Tests applicable to devices with leads and tips. Soldering tests for surface mount devices (SMD) are described in IEC EN 60068-2-58.

This standard provides procedures for determining the solderability and resistance to soldering heat of devices in applications using solder alloys that are eutectic or near-eutectic tin-lead (Pb) or lead-free alloys. The procedures in this standard include the solder bath method and the soldering iron method.

The purpose of this standard is to ensure that the solderability of the component lead or termination meets the relevant solder joint requirements of IEC 61191-3 and IEC 61191-4. In addition, test methods are presented to ensure that the component body can withstand the heat load it is exposed to during soldering.

The solder bath shall be adequately sized to accommodate the samples and contain sufficient solder to maintain solder temperature during testing and to prevent contamination levels applicable to the type of solder used for testing from being exceeded. Unless otherwise specified in the relevant specification, the solder bath depth should not be less than 40 mm and the volume should not be less than 300 ml.

Samples should be visually inspected and checked electrically and mechanically if required by the relevant specification. The soldering immersed surface should be covered with a solder coating with no more than small amounts of diffuse imperfections such as pinholes or unwetted or unwetted areas. All leads will exhibit a defect-free continuous coating of solder for a minimum of 95% of the critical area of any single lead. For solder alloys containing lead (Pb), the solder should be smooth and shiny.

EUROLAB assists manufacturers with IEC EN 60068-2-20 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.