Construction applications and equipment installations in earthquake-prone areas pose a special set of challenges for engineers. No structure can be isolated from seismic activity.

Recognizing this hazard, it has adopted codes and standards governing judicial powers in seismically active areas. These standards ensure that structures and equipment are used to maintain their integrity despite earthquakes, and seismic testing is a vital part of the validation of prototypes and designs. Even if there are no specific codes and standards in a particular earthquake-prone jurisdiction, engineers may still need to reassure their designs will withstand a certain amount of seismic activity. This helps protect equipment and provides security to staff.

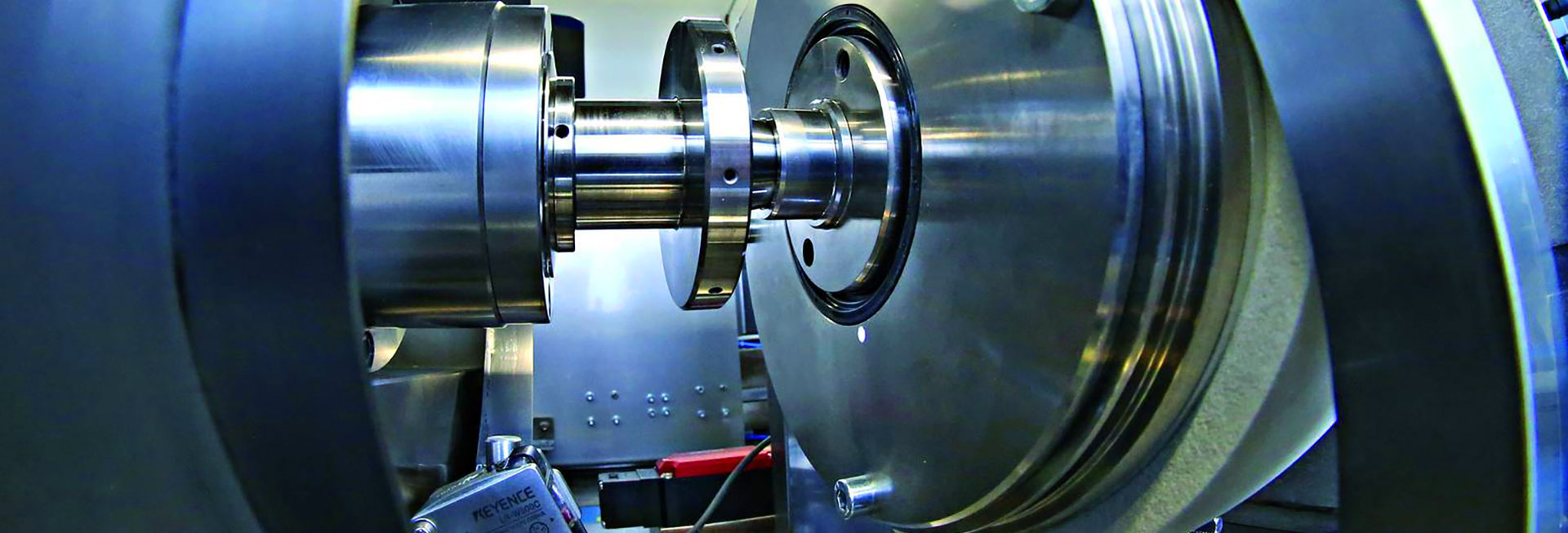

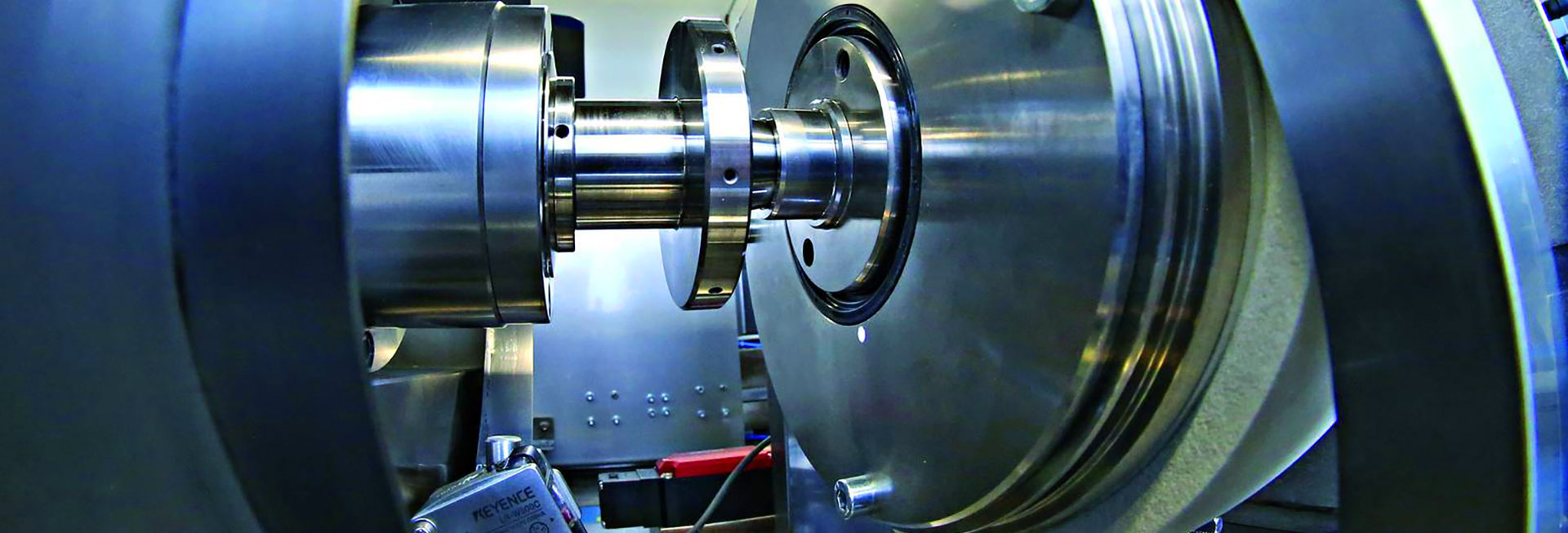

Besides having international accreditation, OLUROLAB also has A2LA ISO 17025 laboratory accreditation. Our seismic testing equipment includes multiple uniaxial, triaxial, biaxial seismic machines. With this level of capability spreading from shore to shore, we are strategically positioned to provide excellent service to our customers. We can test as long as the test item fits on one of our shaker tables and without exceeding the weight limit.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.