The ever-evolving electronics industry requires an increasing need for electronic component testing (IC testing) and component verification. The component testing capabilities and the component validation laboratory in EUROLAB perform testing and inspection to determine the appropriate component functionality, verification or error analysis (F / A).

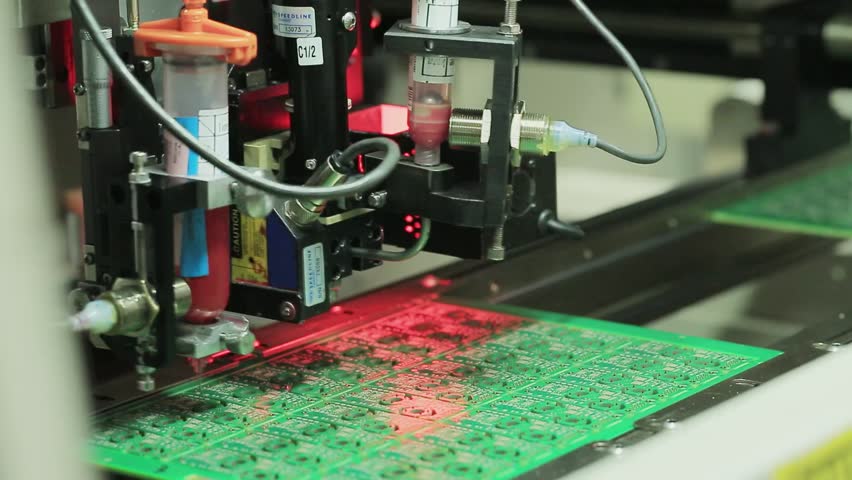

EUROLAB's microelectronic testing and engineering laboratory provides unparalleled excellence in integrated testing and engineering services that support the industry, from early chip design to volume production, to companies worldwide. The scope of testing includes both open-hole and Surface Mount Technology (SMT), flip-chip, BGA, QFB and QFN packages. Access our unique knowledge base to help you design, develop, test, analyze and debug even your most demanding projects. Improved product design, improved reliability and product quality are just a few of the valuable results you will achieve by testing your products for compliance with electrical operating parameters. Component testing can be done as an independent analysis of the electrical properties of the product, or in conjunction with environmental simulation.

It is important to note that when it comes to protection against counterfeit ingredients, component counterfeiters are constantly evolving and improving their techniques. The electronics industry has seen a significant increase in the distribution of counterfeit components / ICs and defective components as new and unused.

Counterfeit components are not easily recognized. These may be low cost parts with part numbers that match, mark or hide a higher priced military part; old pieces recovered from scrapped PC cards; or defective products discarded by reputable manufacturers and distributors. EUROLAB can provide an independent third-party testing program to detect and identify counterfeit components before filtering the electronic supply chain.

EUROLAB has staff, technology and resources to accurately examine, detect and identify counterfeit components and to verify whether a part has been replaced by examining and verifying the following features:

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.