In the event of field failure return, electrochemical migration test (ECM) is performed. The metal transition between the isolated conductors in a completed printed circuit assembly can produce a short circuit.

Ions on the printed circuit mounting surfaces can cause short circuits. In simple terms, shorts are formed if the space between the conductors is bridged by dendrites formed by re-deposited metal ions. This metal migration is best described by IPC as the reverse coating of conductors in the presence of ions, water and electrical potential.

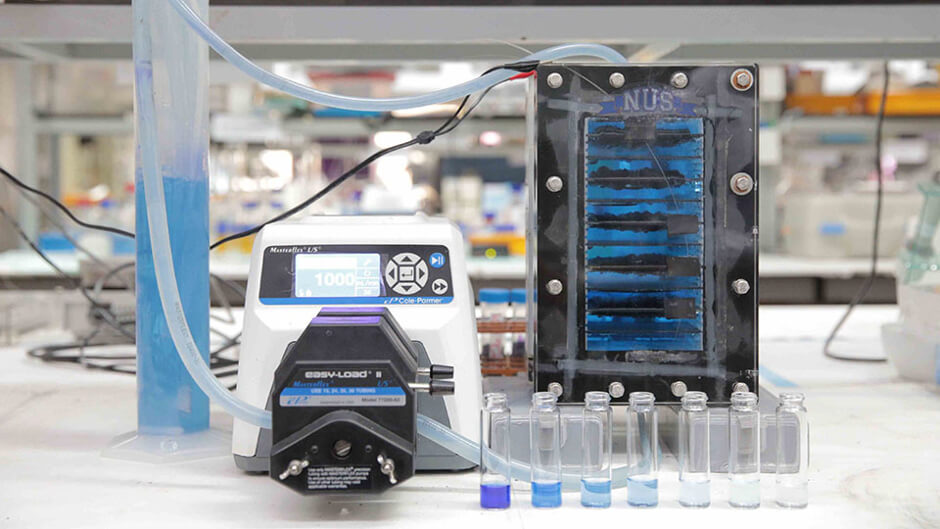

The electrochemical transition test can also be used to evaluate the tendency of a soldering product to contribute to the development of leakage current in electrically isolated circuits. We want to make sure that IPC or Bellcore qualified soldering products that pass the ECM test are selected. Examples of products that require ECM testing are solder and solder masks containing flux.

When dendritic growth occurs in the field, it is often difficult to diagnose. Since dendrites are fragile, they have low current carrying capacity. This fact causes these short circuits to form and burn over and over again. Typically, a full root cause failure analysis is required by an experienced testing laboratory. OLUROLAB has all the resources and experience to discuss, develop, perform and interpret ECM testing and results.

Electrochemical migration (ECM) errors can be difficult to isolate. Dendrites can occur and disappear in a few minutes. These intermittent malfunctions can lead to disastrous results. The intermittent short circuit in the printed circuit assembly (PCA) can cause a plane to crash or the heart / lung machine to stop.

In the event that dendritic growth is suspected or observed in a field failure return, it is recommended to evaluate the risk of this failure occurring in the remainder of the product. The steps outlined below are not the “best” way to evaluate the leakage current development trend of a process as it is a reactive approach, but it can be useful in predicting future risk.

A better way to evaluate the risk of leakage current development is a preventive approach. The first step in reducing the risk of ECM failure is to purchase ionically “clean” boards and components, and to select and handle soldering pastes and fluxes that meet the requirements of an international standard such as IPC J-STD-0043.

The second step to reducing the risk of ECM failure is to evaluate the assembly process. Contracted Manufacturers (CMs) and / or Original Equipment Manufacturers (OEMs) are responsible for conducting this risk assessment. One way to evaluate the effectiveness of the assembly process is to fully rebuild the steps they use in their processes and evaluate the product with an accelerated reliability test. Manufacturers may choose to evaluate their processes using a Surface Insulation Resistance (SIR) test with temperature and humidity, as they want to simulate the exposure of their products to the field. PCAs are used in products that are exposed from cold and dry environments to hot and humid environments, usually fluctuating between the two.

Companies that are at the forefront of product evaluation take the SIR test beyond routine. As the printed circuit board industry switches to thin-curtain, low-void, lead-free products, the risk of ECM failure increases day by day. Companies that need the most reliable PCA (IPC Class 3 High Performance Electronic Products) possible want to evaluate the impact of these mounting changes on long-term performance.

You can contact our expert team for any questions and problems regarding electrochemical migration.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.