EUROLAB, together with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 62899-402-3 testing. IEC EN 62899-402-3 specifies the optical measurement method for obtaining two-dimensional images of voids and obtaining void-related attributes in dried or hardened printed patterns that are part of electronic products in the printing field. Measurable gaps using this standard are limited to those that can be distinguished by optical image measurement.

This standard contains basic information about measuring voids in a printed model in printed electronics. In this standard, void is defined as a very small, unpatterned part of a printed pattern resulting from the printing condition and ink properties and that is processed in two dimensions on a substrate. The terms gap and pinhole used in the electronics and graphic printing industries seem to differ from the terms used in this standard. There can be three types of material absence in the mold.

First, a lack of material inside the solid model, often referred to as a vacuum in the electronics industry. In this case, there is a void inside the model, but a two-dimensional (2D) top view does not show any defective areas. Therefore, it cannot be defined in the graphic printing industry where only two-dimensional (2D) images are meaningful.

Second, there may be a hole penetrating the substrate from the surface of the printing layer. This situation, which can be observed as a hole in the printing field, is called a pinhole in the electronics sector and a gap in the graphic printing sector.

The third is a deep hole that does not penetrate the substrate, so it appears as a hollow in the 2D top view of a print image. In the electronics industry, this is called a hollow or dimple, and in the graphic printing industry it is generally referred to as a hollow or void.

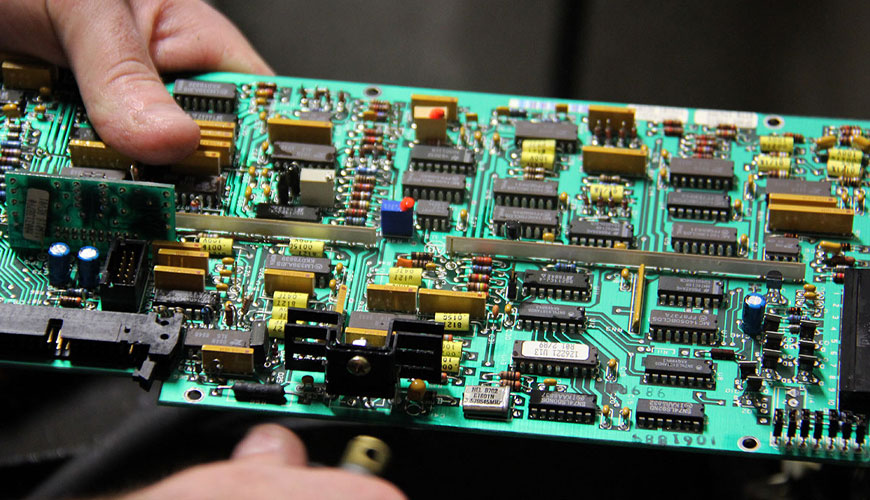

This standard deals with the second and third cases and focuses on the 2D view of the printed model; therefore, the term blank is used in this document according to the definition commonly used in the graphic printing industry. In order for the devices to perform stably and reliably, the printed plates that make up the printed electronic devices to be commercialized must be free of cavities. Detection and analysis of gaps in the pattern can provide guidelines for assessing the printability of the process, inks and equipment, so it is possible to manage and control the performance of printed electronic devices by measuring and analyzing gaps in the patterning.

EUROLAB assists manufacturers with IEC EN 62899-402-3 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.