EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 62485-2 testing. IEC EN 62485-2 applies to fixed secondary batteries and battery installations with a maximum voltage of DC 1 500 V (rated) and describes basic precautions for protection against hazards arising from:

This International Standard provides requirements on safety aspects related to installation, use, inspection, maintenance and disposal.

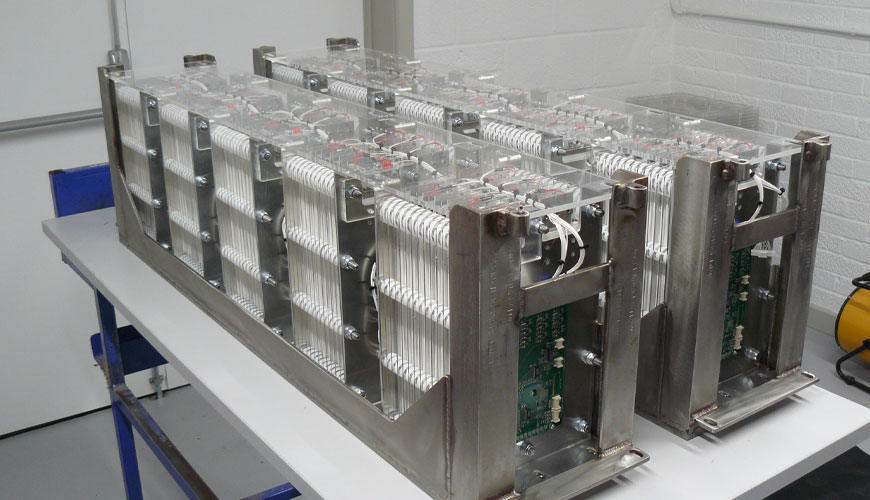

The described safety requirements include safeguards against hazards posed by electricity, electrolyte and explosive gases when using secondary batteries. In addition, measures are described to ensure the functional safety of batteries and battery installations.

This safety standard is effective from the date of issue and applies to all new batteries and battery installations. Previous installations are intended to comply with current national standards at the time of installation. This standard applies in case of redesign of old facilities.

Examples for main applications:

In addition to the hazard of electric shock, current flow in battery systems can cause other hazards. This is because in fault situations very high currents can flow and the voltage at the battery terminals cannot be turned off.

Electrical energy stored in cells or batteries can be released accidentally and uncontrollably due to short-circuiting of the terminals. Due to the significant amount of energy, the heat generated by the high current can cause molten metal, sparks, explosion and evaporation of the electrolyte.

EUROLAB assists manufacturers with IEC EN 62485-2 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.