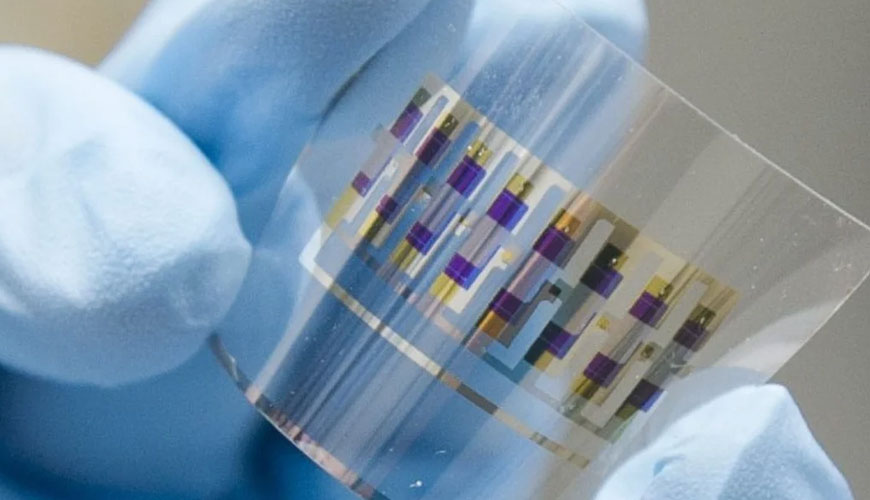

EUROLAB, together with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 62899-503-3 testing. IEC EN 62899-503-3 specifies a contact resistance measurement method for printed thin film transistors (TFTs) using the transfer length method (TLM). The method requires the fabrication of a test element assembly (TEG) with varying channel length L between the source and drain electrodes. The method is designed for quality assessment of TFT electrode contacts and is suitable for determining whether the contact resistance is within a desired range.

In a thin-film transistor (TFT), contact resistance occurs at the gate, source and drain electrodes, and the contacting interfaces in the TFT semiconductor layer. It reduces the effective voltage applied to the source and drain electrodes, while the contact resistance at the gate electrode is negligible. Therefore, evaluation of contact resistance can provide important information regarding the performance characteristics of printed TFTs.

Especially for printed electronics, contact resistance varies with materials used, printing processes and time series variation because the interface is made of simple contact obtained by additive manufacturing rather than a connection obtained by vacuum deposition and etching processes. Therefore, the performance of the printed TFTs is greatly affected by the value of the contact resistance. Therefore, a change in contact resistance is considered to be a key factor for an accurate interpretation of the performance, lifetime, and reliability of a printed TFT.

Various techniques can be used to determine the contact resistance, including but not limited to the two-prong contact method, the four-prong contact method, the six-prong contact method, the transfer length method, and the scanning probe potentiometer technique.

The transmission length method (TLM) has a particularly practical advantage because the supplier can simultaneously test separate devices with the same structure as the original printed TFT on a common substrate. Also, TLM is cost-effective because the user can measure the apparent contact resistance without using expensive equipment. Therefore, using TLM, supplier and user can change contact resistance, which is an important parameter of TFT for reliability assessment as part of supply chain services.

EUROLAB assists manufacturers with IEC EN 62899-503-3 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.