EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 60695-5-1 test. This part of IEC EN 60695 provides guidance on:

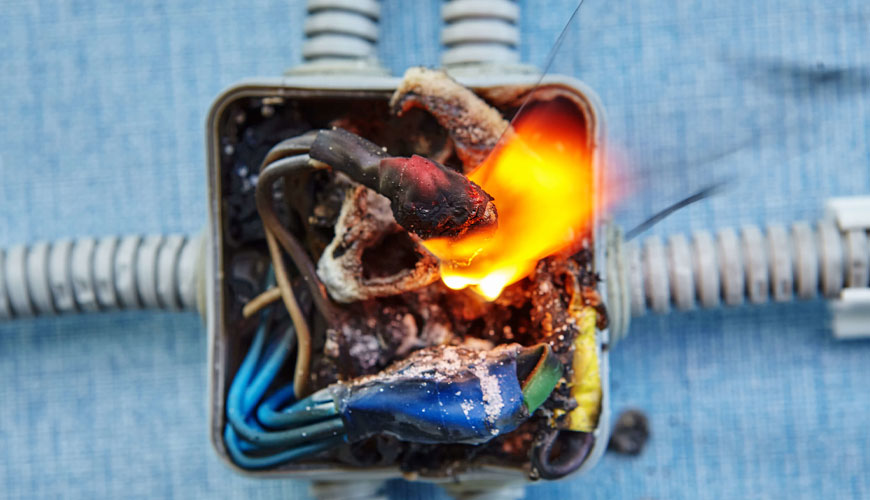

The risk of fire must be considered in any electrical circuit. In relation to this risk, circuit and equipment design, selection of components and selection of materials should contribute to reducing the probability of fire, even in the event of foreseeable abnormal use, failure or malfunction. The practical aim should be to prevent ignition from electrical fault, but if ignition and fire occur, control the fire preferably within the confines of the enclosure of the electrotechnical product.

All fire wastes are corrosive to some degree and the level of corrosion potential depends on the nature of the fire, the combination of combustible materials involved in the fire, the nature of the substrate under attack, and the temperature and relative humidity of the environment. where corrosion damage occurs. Fire wastes from electrotechnical products, furniture, construction materials, etc. There is no evidence that it carries a greater risk of corrosion damage than fire waste from other products such as

The performance of electrical and electronic components can be adversely affected by corrosion damage when exposed to fire waste. A wide variety of combinations of small amounts of flue gases, smoke particles, humidity and temperature can provide conditions for electrical component or system failure due to breakage, overheating or short circuit.

Studying corrosion damage requires an interdisciplinary approach that includes chemistry, electricity, physics, mechanical engineering, metallurgy, and electrochemistry. All of the above has been taken into account in the preparation of this part of IEC EN 60695-5.

EUROLAB assists manufacturers with IEC EN 60695-5-1 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.