With its state-of-the-art accredited laboratories and expert team, EUROLAB provides precise and fast testing services within the scope of IEC EN 62899-202-7 testing. IEC EN 62899-202-7 provides a test method for measuring the peel strength of a printed layer on a flexible substrate. This method requires peeling off the flexible substrate instead of an additional metal electroplating on the printed layer.

The method described in this standard can be used to compare the peel strength of printed layers on the same flexible substrate and thickness conditions. It can be used when the adhesion between the printed layer and the flexible substrate is weaker than any other interface between the printed layer and the adhesive, the adhesive and the panel.

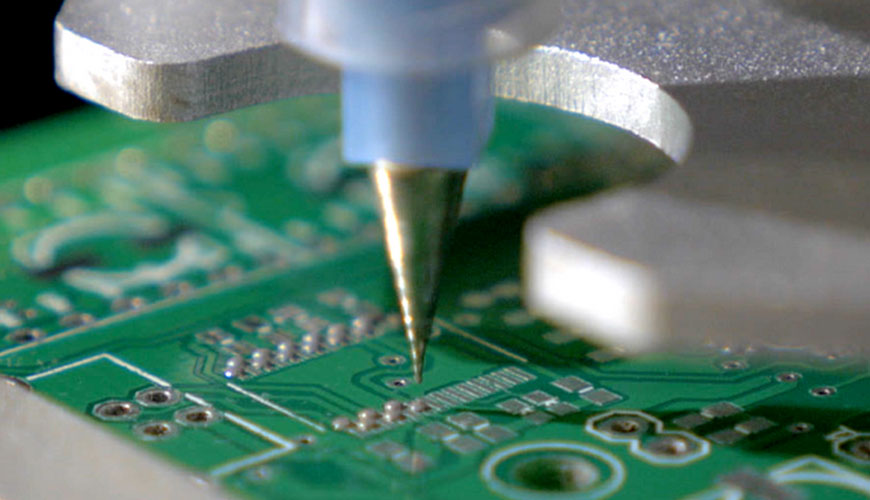

A layer printed on a flexible substrate is commonly used as an electrode or interconnect for flexible devices. An integral component of this conductive body of the devices is the conductive composite material and is commercialized as conductive ink.

A simple tape test method is commonly used for qualitative adhesion measurement, but it cannot be used to measure strong adhesion between the printed layer and the flexible substrate. In the printed circuit industry, a traditional peel test method is widely used to evaluate the adhesion between a thin printed sheet with a dense microstructure and a flexible substrate.

The peel strength value can be measured after an additional metal electroplating treatment on a thin printed layer to increase the printed layer thickness to ensure a stable grip in an adhesion testing machine. However, it is not suitable for testing a printed sheet that has a porous structure that is susceptible to contamination of the interface between the printed sheet and the flexible substrate during the galvanic coating process.

Therefore, a quantitative and reliable adhesion test method is used to measure and understand the interfacial adhesion of the printed layer to the flexible substrate and its long-term reliability.

In this standard, a new standard test method is proposed for measuring the peel strength of a printed layer on a flexible substrate. This method requires peeling off the flexible substrate instead of an additional metal electroplating on the printed layer. It is useful to monitor and compare the thickness dependence of the peel strength of a layer on the same flexible substrate.

EUROLAB assists manufacturers with IEC EN 62899-202-7 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.