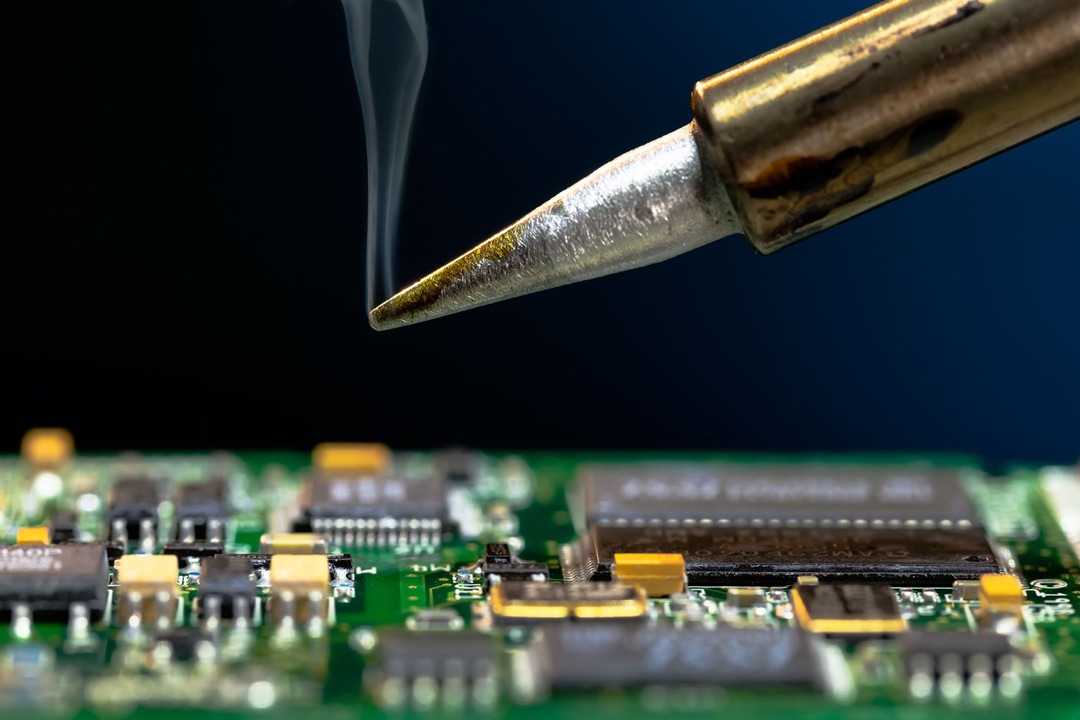

Solderability testing method provides optional conditions for preconditioning and soldering to evaluate the solderability of instrument pack terminations. It provides procedures for immersion and solderability testing of hole, axial and surface-mounted devices, and surface-mount process simulation testing for surface-mounted packages.

The solderability test provides a way to determine the solderability of the instrument pack terminations intended to be bonded to another surface using SnPb or Pb-free solder. The procedure, which is considered destructive, will test whether the packaging materials and processes used during the manufacturing processes produce a component that can be successfully soldered in the next level assembly.

There are two methods of solderability testing. Method 1 is known as "immersion and appearance" for leaded and lead-free terminations. This method includes preconditioning, flux application, and immersion of terminations in molten solder, if any. Method 2 is a Surface Mount Process Simulation test.

The purpose of this test method is to provide a way to determine the solderability of device package terminations intended to be joined to another surface using lead- (Pb-) solder for connection or Pb-free solder.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.