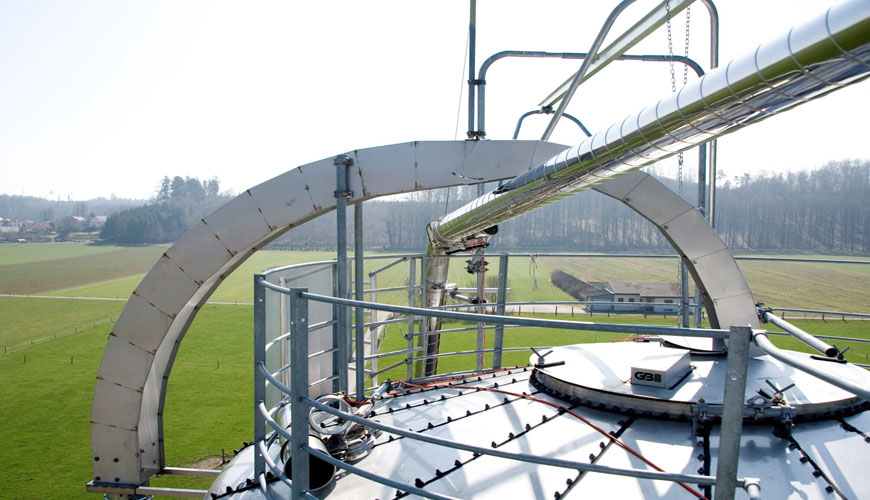

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of EN 617 testing. This European standard covers technical requirements to minimize hazards. These hazards may arise during the operation and maintenance of equipment used to store bulk materials in silos, hoppers, drums, hoppers and their built-in inlets and outlets. This standard deals with safety-related technical verification during commissioning.

The safety requirements or precautions in this standard apply to equipment used in all environments. However, in severe conditions additional risk assessment and safety measures need to be considered, eg. Low or high temperatures outside the range covered by EN 60204-1, corrosive environments, strong magnetic fields, radioactive conditions and bulk materials to be stored include flows that can cause an inherently hazardous situation.

This standard does not cover requirements for:

Each air cannon or other high pressure gas material flow assist device operating on the principle of fluid injection shall be able to be separated from the power supply by a lockable control valve. It will also be possible to depressurize them.

It shall be equipped with minimal level indicators to prevent the silo from overflowing when full or creating a spill when an empty silo is unintentionally filled with an open door. If the bulk material creates additional risks in cases of overflow and spillage (such as burning, explosion, etc.), the level indicators will be locked with the possibility of filling and discharging. In cases where the vehicle is charged by gravity, this interlock should prevent access to the charging area.

When silos operate under intended or foreseeable conditions of overpressure or underpressure, they must be equipped with corresponding pressure compensating devices to prevent overvoltages which can also cause loss of stability.

In silos equipped with rupture discs or diaphragms, these should be located at the top of the silo or at the top of the silo symmetrically with respect to the longitudinal axis of the silo. The silo and fixation devices are to be designed to withstand the reaction from the explosion discharge that could cause the silo to topple.

EUROLAB assists manufacturers with EN 617 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.