EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 61191-3 testing. IEC EN 61191-3 specifies requirements for lead and hole solder assemblies. The requirements relate to assemblies that use purely through-hole mounting technology (THT) or to THT portions of assemblies that incorporate other related technologies (eg, surface mount, chip mount, terminal mount).

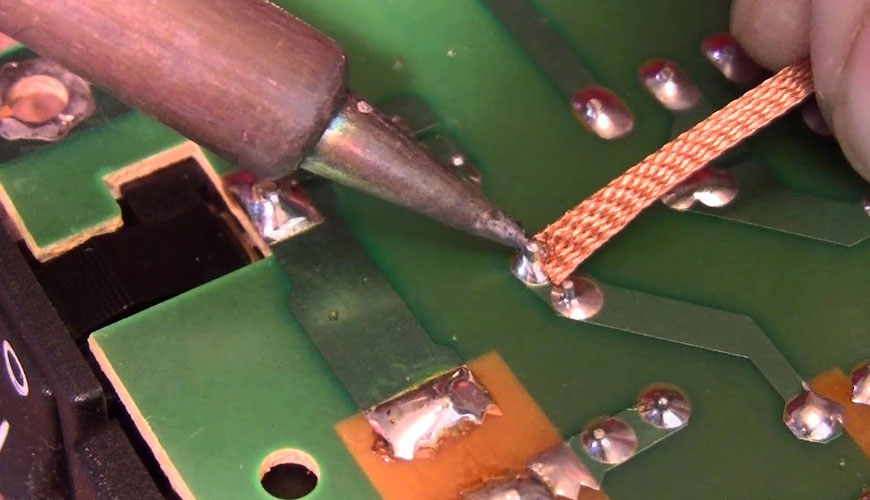

This clause covers the assembly of components where leads are inserted into through holes and soldered by machine or manual processes. Part and component cables must be preformed to the final configuration prior to assembly or installation, excluding the final riveting or holding bracket.

Where tempered wires need to be cut, applicable work instructions will specify cutting tools that do not give harmful shocks to the internal connections of the components.

When manually riveted, the riveted portion of wire or lead must be routed along a printed conductor connected to earth. Cables at opposite ends or sides of a component should be routed in opposite directions. When automatically riveted, the orientation of the rivet relative to any conductor is arbitrary. Hand-formed rivets for non-axial leaded components must be oriented radially from the center of the component when the termination area array on the printed circuit board is patterned for this type of radial orientation.

Partially riveted ends must be bent sufficiently to provide the necessary mechanical restraint during the soldering process. Alternative twist directions can be used. Diagonally opposite corner ends on double-row packages (DIPs) can be partially riveted to hold parts during soldering operations. DIP ends should be bent outward from the longitudinal axis of the stem.

Components should be mounted in such a way that there is a visible gap between the plating meniscus on each end and the solder joint. Trimming the component coating meniscus is prohibited.

EUROLAB assists manufacturers with IEC EN 61191-3 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.