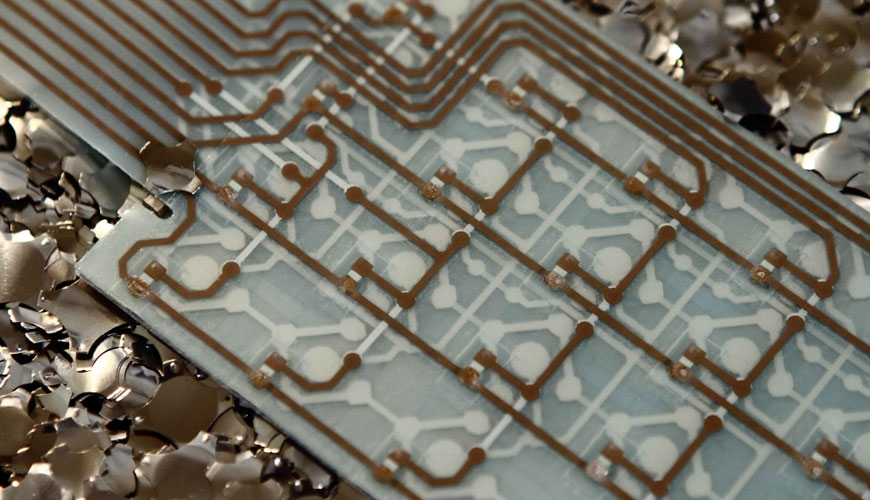

EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 61249-5-1 test. This standard specifies the characteristics of copper foil intended for use in the manufacture of copper clad laminated sheets and copper clad flexible materials used in the manufacture of printed sheets.

The primary measure of the amount of copper foil will be mass per unit area with applicable tolerances. Copper foil thicknesses corresponding to the mass values specified per unit area will be accepted for information purposes only.

The force required to strip the copper foil from the resin of the base material must meet the values listed in the relevant specification of IEC EN 61249 or be as agreed between the purchaser and the supplier.

Both sides of type E and type R copper foils shall be substantially free of resin tears, wrinkles, dirt, oil, corrosion or corrosion products, salts, grease, fingerprints or other defects that could adversely affect the quality of the copper plating.

After removing the copper foil laminated to the base material by etching, no more than traces of the process should remain on the base material. No measurable change in the properties of the laminate caused by the process will occur. A certain unevenness in the color of the process is permissible, provided that there is no difference in the properties of the copper-clad laminate between areas showing different colors of the process.

Copper foil sheets (cut panels) must be sealed with a lubricant-free polymer film so that properties remain within given requirements for a period of 90 days after shipment. Sealing sheets should be placed on a suitable solid and smooth base and covered with a cover material of comparable stability and smoothness. The page content of the package will be agreed between the buyer and the supplier.

EUROLAB assists manufacturers with IEC EN 61249-5-1 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.