EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of IEC EN 61249-8-5 testing. IEC EN 61249-8-5 defines the criteria and method for obtaining maximum knowledge and confidence about cured permanent solder mask and coating material evaluated with minimum test redundancy.

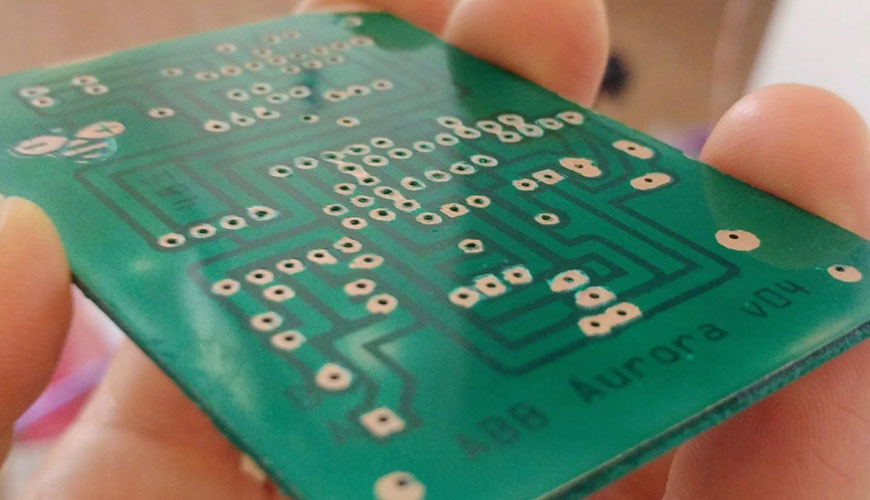

This specification should specify requirements based on applicable test methods and conditions for evaluating a solder mask and coating material and determining the acceptability of its use on a printed circuit board. These same requirements will also be used to qualify a printed circuit board manufacturing process based on compliance criteria defined by the reliability requirements of the end-use environment.

The solder mask materials described herein aim to prevent or minimize the formation and adhesion of solder balls, solder bridging, solder build-up, and physical damage to the printed circuit board substrate when applied to the printed cardboard substrate. Solder mask material will retard electromigration and other forms of harmful or conductive growth.

This includes computers, telecommunications equipment, advanced business machinery, instruments, and some non-critical military applications. Solder mask and coating material on printed boards in this class are suitable for high performance commercial and industrial products where long performance life is desired but interrupted service is not life threatening.

Solder mask, coating material or printed sheets to be coated shall be free of harmful substances and formulated or prepared to meet the requirements specified in this specification. The solder mask supplier will be responsible for providing objective evidence that the supplied solder mask or coating materials have been processed according to the supplier's instructions to ensure a level of hardening that meets the acceptance criteria.

Solder mask or coating materials shall be suitable for application and use in printed boards and shall be chemically, physically, environmentally and electrically compatible with the building materials. These materials will not degrade the materials used in printed card assemblies or the components mounted/attached to them. The materials do not corrode any metal coated.

EUROLAB assists manufacturers with IEC EN 61249-8-5 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.