It generally includes application-specific integrated circuits such as complex custom microcode components, programmable logic devices, field programmable gate arrays, or similar electronic components used in the design of aircraft systems and equipment. When designing level D devices, manufacturers can comply with the RTCA DO-254 standard developed by the Radio Technical Aviation Commission (RTCA). In this case, official institutions do not see the need to examine the life cycle data of that device.

If the guidelines and procedures described in the standard “RTCA DO-254 Design assurance guidance for airborne electronic equipment” are followed, there is assurance that the equipment performs its intended functions and meets all applicable airworthiness requirements.

This standard distinguishes between complex and simple electronic equipment and defines five classes of fault conditions, from catastrophic to no-effect. It also provides guidance for each hardware design assurance level associated with a particular fault condition classification.

The guidance of this standard applies to electronic equipment that:

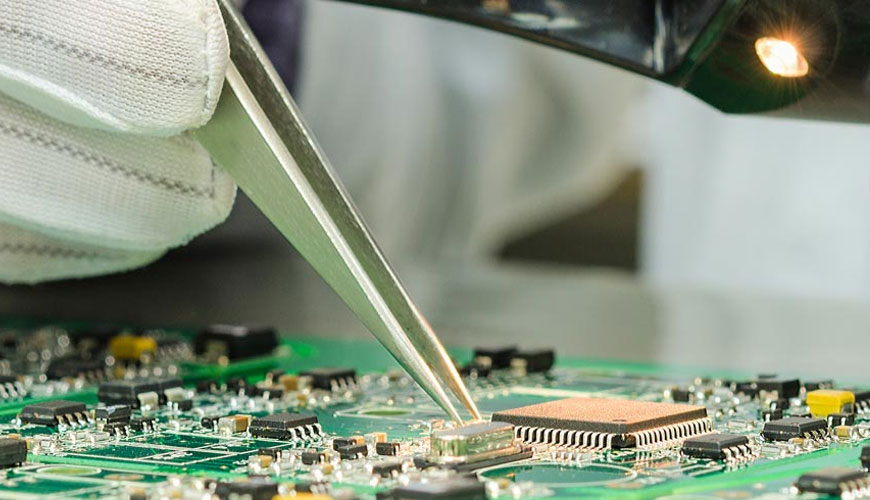

The RTCA DO-254 standard defines the design lifecycle processes for various types of equipment and helps aircraft manufacturers and aircraft electronic systems suppliers to ensure that equipment safely performs its intended function.

Briefly, this standard provides a structured hardware lifecycle with three main parts: planning, hardware design processes, and supporting processes. In addition, this standard covers all electronic devices that fly or can crash and pose a danger to humans.

Among the numerous test, measurement, analysis and evaluation studies it provides for businesses in various sectors, our organization also provides testing services within the framework of the design assurance guide for electronic equipment in the air, within the scope of RTCA DO-254 standard, with its trained and expert staff and advanced technological equipment.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.