Hydraulic aviation components require special care to prevent accumulation of particles, oxidation and other residues that can affect critical performance factors. Regular hydraulic cleaning is an essential part of ongoing maintenance and should also be done during repair or installation.

EUROLAB offers high-controlled hydraulic cleaning services for essential aviation components. We can also perform fluid testing to determine various factors that can affect the performance of your hydraulic equipment, as well as particle analysis, which determines the chemical structure of residues on stainless steel, aluminum, titanium, beryllium and composite components.

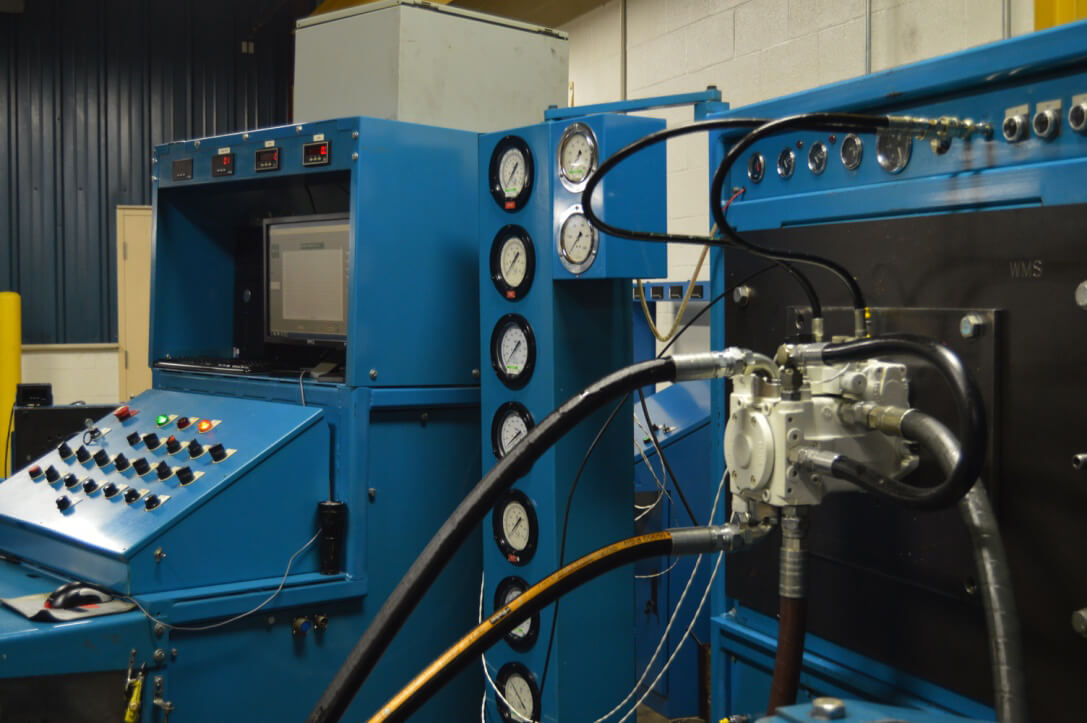

We clean and analyze hydraulic components and assemblies in our Class 10.000 clean room. Our capabilities include cleaning using aqueous detergents, a variety of compatible solvents or system hydraulic test fluids, 50.000 psi (345.000 kPa) using DI (Deionized) water or hydraulic fluid of components or assemblies, and 20.000 psi (138.000 kPa) GN2 using proofing and leak testing. it is available. The cleaned and tested equipment can be stored in the hydraulic fluid and sealed or packaged in nitrogen-cleaned envelopes. Some of EUROLAB's parts for hydraulic service include valves, regulators, accumulators, pistons, actuators, transducers, piping and piping, control and distribution manifolds, servos and storage tanks.

EUROLAB provides expert service for on-site hydraulic and mineral oil systems and components cleaning. Whether after a new construction, modification of an existing system or just in preventive maintenance, removing corrosive contamination from internal pipes and rotating machines extends equipment life and prevents premature failures. By using state-of-the-art high-capacity pumps and submicron filtration, it cleans the blocked detergents, citric or phosphoric acid, solvents or hydraulic fluid or lubricating oil from circulation in a complete system at operating temperature, pressure and flow rate.

Typical service areas in the field include hydraulic or mineral oil systems in power generation facilities, factories, steel mills, mining operations, launch vehicle ground support equipment, food processing facilities and even amusement parks. In addition to complete cleaning, passivation and testing, we can remove abrasive particles and polish existing lubricating oil or hydraulic fluids in tanks, accumulators, drums or complete systems.

Hydraulic cleaning is just one of many services we offer to our aerospace industry customers. By allowing EUROLAB to manage the cleaning and testing for you, you get a certified clean, functionally tested system without having to manage another project.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.