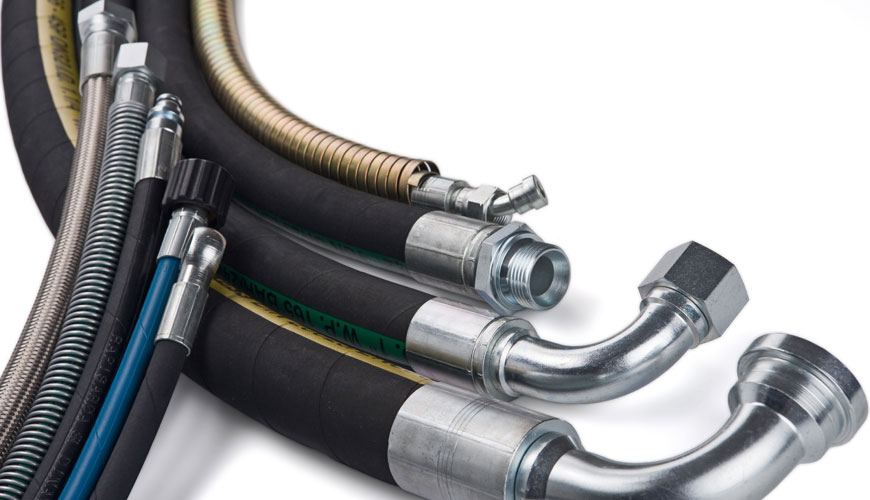

EUROLAB laboratory provides testing and compliance services within the scope of SAE J343 standard. This SAE standard provides methods for testing and evaluating the performance of SAE 100R series hydraulic hose and hose assemblies (hose and attached end fittings) used in hydraulic fluid power systems.

Special tests and performance criteria for evaluating hose assemblies used in hydraulic service comply with the hose requirements in the relevant specifications of SAE J 517. This standard also provides a uniform tool for evaluating and testing the performance of hydraulic hose assemblies.

Unless otherwise specified in this standard or other SAE standards, tests shall be conducted at the applicable ambient temperature of the test facility.

Water or another liquid suitable for the hose being tested should be used as the test medium. The use of air and other gaseous materials as test media should be avoided due to the risk to operators. In special cases where such environments are required for tests, stringent security measures are mandatory.

It was also emphasized that when a liquid is used as the test medium, it is important to expel all the air from the test piece due to the risk of injury to the operator due to the sudden expansion of the compressed air released when the hose bursts. .Hydrostatic pressure unused hose or hose assemblies with end fittings attached for a maximum of 30 days. Increase the pressure according to the following paragraph until the hose or hose assembly fails.

The rate of pressure rise should be constant and selected such that for hoses up to a nominal inside diameter of 51 mm, the hose or hose assembly fails after a period of 30 seconds to 60 seconds. For hoses with nominal inside diameters greater than 51 mm and less than or equal to 250 mm, the time required to reach hose or hose assembly failure should be between 60 seconds and 240 seconds.

Reject any hose or hose assemblies that show signs of leaks, hose bursts, or malfunctions below the specified minimum burst pressure. The location, pressure and mode of the fault should be recorded in the test report.

EUROLAB assists manufacturers with SAE J343 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.