Advanced laboratories also provide product composition analysis services within the scope of substances and formulated product tests, including physicochemical tests, shipping, hazard assessments, technical and safety data sheets, shelf life studies and biodegradability analysis. These services include analytical programs to detect and track counterfeit or manipulated products.

For this purpose, advanced analytical equipment and fingerprint technology are used to develop chemical databases of various materials and to analyze product composition. Some of the product composition analysis methods offered in this context are: melting and boiling points, density of liquids and solids, vapor pressure, pH value, acidity and alkalinity, physical state (color and odor), solubility (water and organic solvents), flammability, flash point. explosive properties, oxidizing properties of solids and liquids, pyrophoric properties of solids and liquids, particle size distribution, thermal stability, autoignition temperatures of liquids or solids, viscosity and curing rate.

Product composition or material composition analyzes provide benefits in many ways. For example,

With product composition studies, accurate data are obtained for materials or raw materials, it is ensured that the raw materials meet the product requirements, material quality control is assisted and product quality is ensured. In this way, businesses analyze, compare, improve their existing formulations and increase the performance of existing products. If the product is unqualified, it is easier to determine whether the problem is due to the wrong formula or the mixing of some impurities in the production process, with product composition analysis.

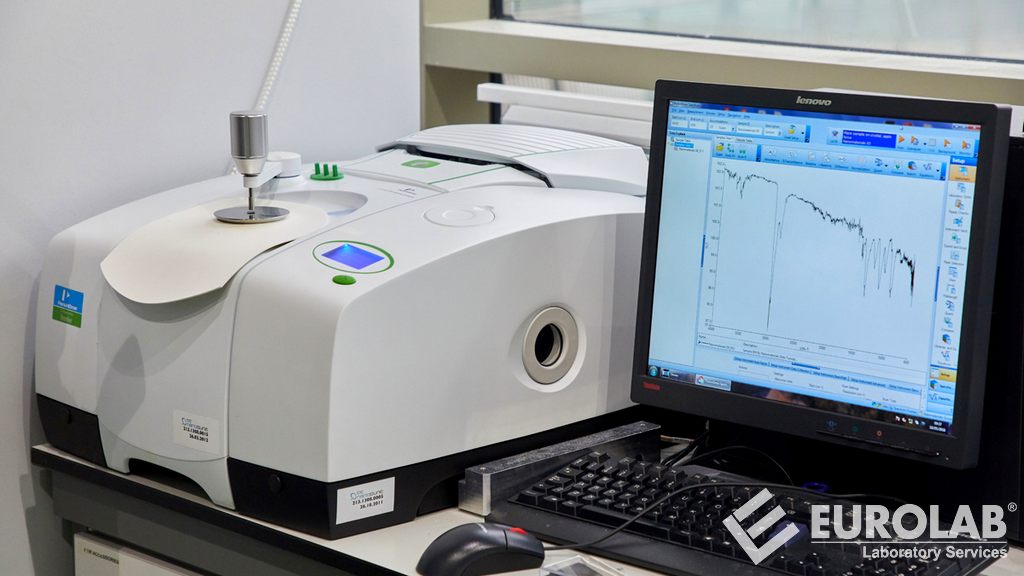

FTIR, Fourier transform infrared spectroscopy (Fourier transform infrared spectroscopy) is a fast, economical, easy and non-destructive analysis method. FTIR spectroscopy, product composition analysis method uses infrared light to scan test samples and observe chemical properties, and this technique has been widely used in recent years. This technique is an analytical test method used to identify organic, polymeric and inorganic materials. In fact, FTIR spectroscopy is used to characterize a wide variety of materials. However, this technique is not suitable for many waste materials due to the strong effect of the sample particle size and the inability to measure the absorption of very dark and opaque samples.

When trying to briefly identify an unknown material, FTIR, Fourier transform infrared spectroscopy analysis, is considered a great tool. This technique is well suited for solids, liquids and gases, as well as applicable to pure substances or mixtures. It is possible to make quantitative or qualitative analysis. However, it is not a good technique to measure the trace of contaminants. It describes the bulk materials extremely well. FTIR spectroscopy provides quality control during the manufacturing process when trying to identify or monitor changes in material composition and impurities in raw materials or finished products. FTIR analysis is also useful in complying with regulations such as breathable silica for industrial hygiene in construction and oil fields.

FTIR spectrum is seen as the infrared fingerprint of the material. Qualitatively unknowns are identified by comparison with an extensive FTIR spectrum library. Quantitatively, FTIR analysis is often the first step in the material analysis process because of its speed and simplicity. Material samples as light as 50 milligrams can be evaluated using the FTIR spectroscopy technique. The small sample size allows for selective identification of particles, debris, films or fibers.

FTIR spectroscopy analysis includes the following applications: quantitative scans, qualitative scans, solids, non-aqueous liquids, organic samples, inorganic samples, unknowns identification, impurity screening, soil remedies, paints, coatings, laminates, assessment of purity (raw materials, intermediates and finished products), polymers and plastics (base polymer compounds, additives and organic contaminants), common household items (cleaners and detergents, baking powders and materials, dyes, oils, paper and medicines), fibers (acrylic, nylon, polyester and artificial synthetic fibers such as silk and natural fibers such as cotton, silk and wood), adhesives (glue, epoxy and resin), biodiesel content in diesel fuel.

Our organization provides product composition analysis services with FTIR to demanding enterprises within the framework of national and international standards, with a trained and expert staff and advanced technological equipment, among numerous testing, measurement, analysis and evaluation studies.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.