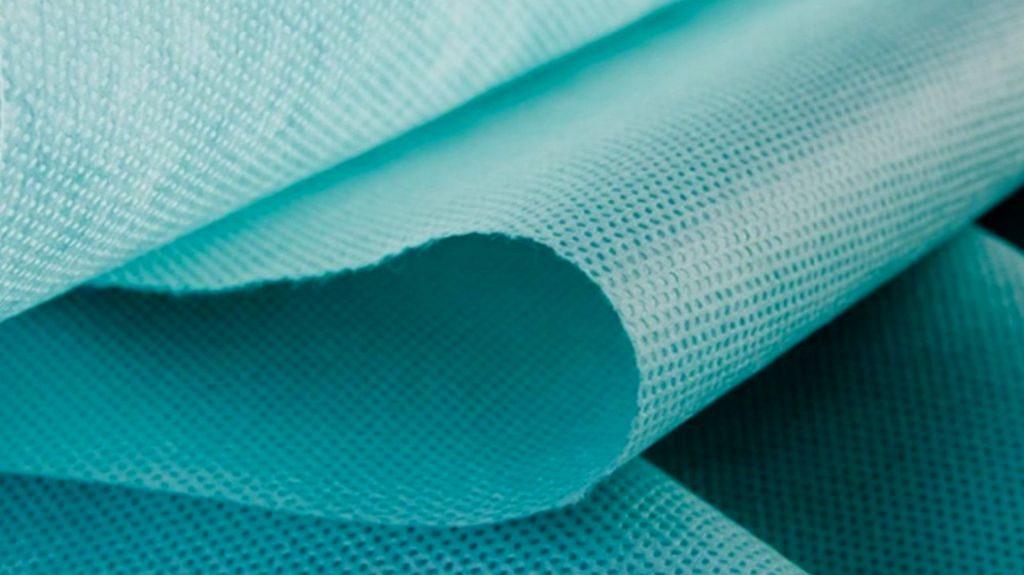

Meltblown fabrics are fabrics with fine fibers that are ideal for filtering breathable particles and provide air filtration applications with excellent barrier and filtering properties. They are perfect for a wide variety of applications such as meltblown nonwoven fabrics, industrial respirators, vacuum cleaner bags, automotive cabin filters and microbiological filters.

Meltblown face mask filter material is a high efficiency particle catcher, or simply a type of HEPA filter. For personal protective equipment masks and respirators, meltblown filters made entirely of polypropylene filtration material are used. This material filters at least 0,3 percent of airborne particles with an average size of 95 microns. The meltblown filter material used inside a face mask or face respirator is therefore considered extremely strong.

The meltblown filter material is rated Level 1 by the American Society for Testing and Materials (ASTM). This level refers to low fluid resistance. When this filter material is used as the inner layer of a face mask made of spubond nonwoven material, the effectiveness of the mask is further increased.

In daily life, newly bought clothes, sheets and other textile fabrics sometimes tend to shrink after one or two washes. This undesirable situation is also valid for washable mask filter fabrics.

The dimensional stability (stability) of the fabric in Meltblown filter fabrics means that the fabric size changes depending on the properties of this material and the potential shrinkage force in the processing process. Facial masks with a strong dimensional stability can be washed many times. Such fabrics do not change their original folds and shapes and do not decrease in size. Fabrics with low dimensional stability generally show shrinkage during processes such as sewing, washing and ironing.

The main factor that causes fabric shrinkage is moisture absorption of the fiber. Also, the tension of the thread and fabric structure It affects the shrinkage. If the twist and volume ratio of the yarn is high, the fabric shrinkage is also high.

Our organization provides tensile testing services within the scope of meltblown fabric testing services to demanding healthcare organizations and manufacturers within the framework of national and international standards, with a trained and expert staff and advanced technological equipment, among numerous testing, measurement, analysis and evaluation studies.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.