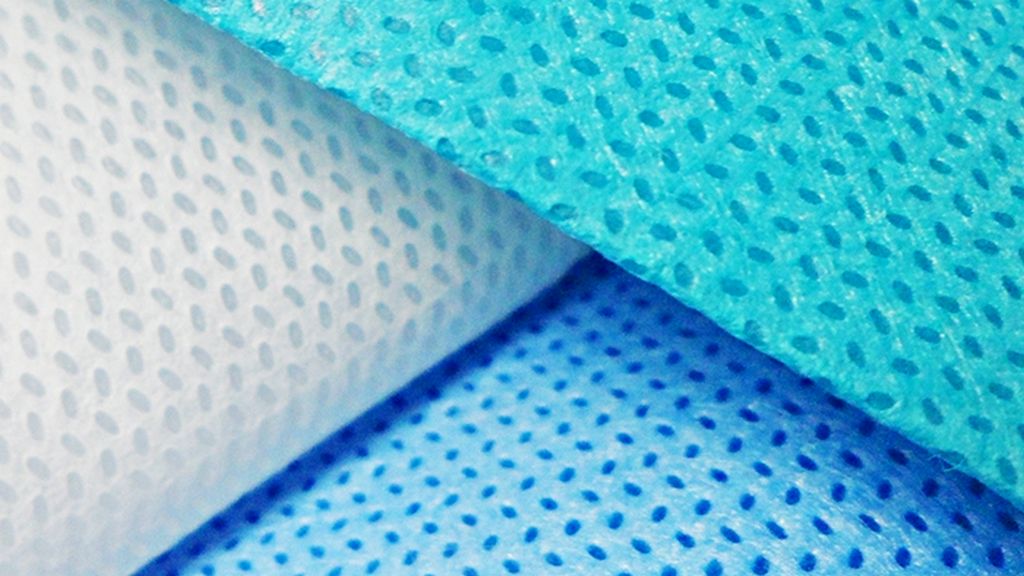

The fabrics that can be used the most in the nonwoven fabric sector are meltblown and spunbond fabrics. Most of them are preferred in medical textile production. In the textile industry, the properties of liquid permeability and wetting back are of great importance according to the areas where these fabrics will be used. For this reason, manufacturers use some hydrophilic chemicals.

Medical textile products are a remarkable branch of technical textiles. Numerous medical textile products such as surgical clothes, drapes, surgical threads, bandages, wet wipes, medical masks, feminine hygiene ties, waterproof bed covers, baby, child and adult diapers and urine retaining diapers are produced.

Hygiene and care products are an important product group for operating theaters, hospital rooms, personnel and patient safety, and some of them are disposable. As such, the demand for these products increases on a global basis and this situation intensifies the competition.

Hydrophilic polypropylene fabrics are preferred in hygiene and care products. Polypropylene fabrics have many physical and chemical advantages and have been the most used raw material source in the nonwoven sector. Meltblown fabrics have this feature. Nonwoven fabrics with different characteristics produced from polypropylene fabrics are used in many areas, from companies producing diapers to food packaging companies, especially medical textile products.

The hydrostatic pressure tests of Meltblown fabrics are based on the AATCC 127 standard developed by the American Textile Chemists and Colorists Association (AATCC). In this standard, the water resistance properties of these fabrics are determined and the hydrostatic pressure test method is described (AATCC MT127 Water resistance - Hydrostatic pressure test).

By performing these tests, the resistance of a fabric against the penetration of water under hydrostatic pressure is determined. The water resistance of the fabrics is also closely related to the structure of the fabric and the water repellency of the fibers and yarns.

Meanwhile, in hydrostatic pressure tests, UluslThe ISO 811 standard developed by the International Standards Organization (ISO) is also complied with. Similarly, this standard provides a hydrostatic pressure test method for determining the resistance of fabrics to water ingress (ISO 811 Textile - Determination of resistance to water infiltration - Hydrostatic pressure test). This test method is applied to all textile materials and is carried out together with the breathability tests of the fabrics.

Our organization provides hydrostatic pressure test services within the scope of meltblown fabric testing services to demanding healthcare organizations and manufacturers within the framework of national and international standards, with a trained and expert staff and advanced technological equipment, among numerous testing, measurement, analysis and evaluation studies.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.