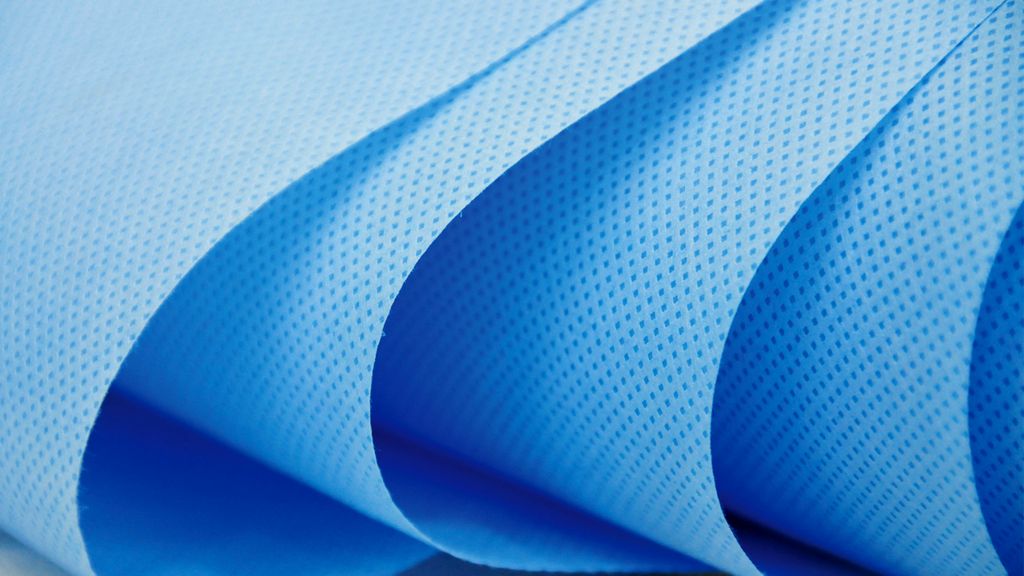

Spunbond fabrics are the most used fabrics in the nonwoven (non-woven fabric) industry. Some of these are generally used in diaper production. However, depending on the use of the fabric, the amount of liquid absorption and rewet properties is important. For this reason, companies that produce spunbond fabric use hydrophilic chemicals. Polyproplin spunbond production technology has developed rapidly in recent years. Polypropylene is produced in the form of granulation (arranging the particle size in the desired way) of the raw material with the melt extrusion method and filaments.

The process of making spunbond fabric (spunbond fabric) combines fabric production with filament production. The high process efficiency and excellent properties of these fabrics enable them to be accepted in different application areas such as civil engineering, automotive industry, shoe industry and packaging industry, especially in medicine and hygiene. It is not easy to control the structure and properties of such fabrics as there are several process parameters that affect the fabric properties as well as the structure and properties of filaments.

Spunbond nonwoven fabrics consist of continuous filaments produced by an integrated process of fiber spinning, networking and bonding. It eliminates intermediate stages in the production process and follows the shortest textile route from polymer to fabric in one step. In this way, production increases and costs decrease.

Today, among the nonwoven fabric production techniques, the largest share is held by areas such as diaper products, medical products, geotextiles, the automobile industry, civil engineering and packaging.

One of the tests applied to verify the quality of non-woven fabrics, including spunbond fabrics, is the GSM test. All fabrics have a certain weight and the quality of the fabrics is defined by the fabric weight expressed in grams / square meter. Square meter grammage (gr / m2) is the area mass of the fabric in a sense and it is accepted as the thickness or density of the fabric in daily life.

Briefly, GSM refers to the meter weight of the fabric. GSM determines the usage area of many fabrics. For example, spunbond + melblown + spunbond fabrics with a weight of 30 grams per square meter are a fabric used in the production of medical mask masks. Medical gowns cannot be made from such a fabric. Heavier for apron and durable 80 grams of spunbond + melblown + spunbond fabric should be used.

For this reason, among the spunbond fabric tests, the GSM test is important in determining the weight and therefore the quality of the fabric.

Our organization provides GSM test services within the scope of spunbond fabric testing services to demanding healthcare organizations and manufacturers, within the framework of national and international standards, with a trained and expert staff and advanced technological equipment, among numerous testing, measurement, analysis and evaluation studies.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.