The AATCC TM163 standard can also be used to evaluate possible color transfer issues with the finish. Some paints are naturally more prone to transfer than others, and some chemical coatings and finishing conditions accelerate transfer.

Storing clothes made with component parts in more than one shade sometimes causes the dye to migrate from one area to another, normally from darker to lighter. This phenomenon is different from the sublimation temperature of dyes and also from non-subliming dyes.

Dye transfer occurs when garments are folded in different hues in close contact with each other. Normally, the amount of dye transferred condenses when moisture is present, so the problem is more severe in hot, humid weather or when garments are steamed just prior to storage. Storage in plastic bags tends to maintain the initial relative humidity of the clothing environment and can aggravate or reduce transfer depending on the condition of the fabric at the time it enters the bag.

This test method can also be used to evaluate possible color transfer that can be expected to occur during extended storage periods. In general, if color transfer does not occur under the conditions specified in the procedure, no problems are to be expected under normal storage conditions or a time delay.

This test method can also be used to evaluate possible color transfer problems with the finish. Some dyes are naturally more prone to transfer than others, and some chemical finishes and finishing conditions accelerate transfer.

The dyed and finished test specimens are sandwiched between a pre-wetted multifibre fabric and a selected second fabric, placed in the Perspiration Tester for 48 hours at room temperature, dried and graded.

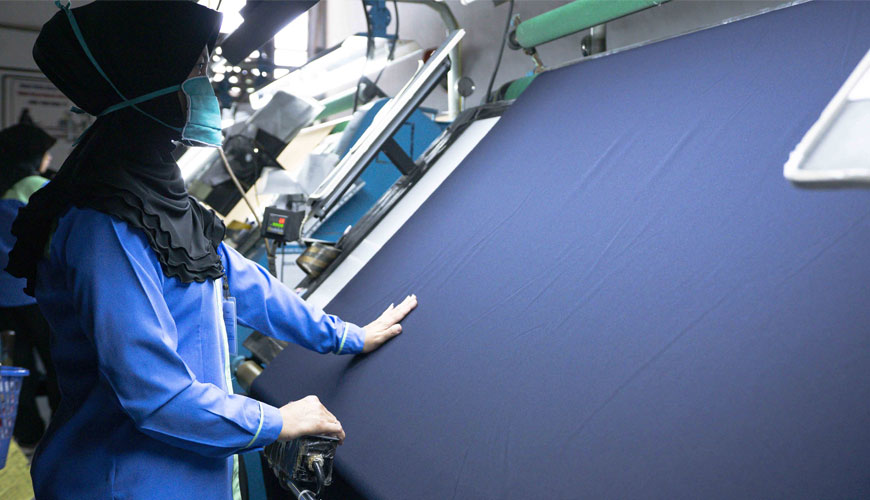

Color fastness is the resistance of a material to change in any of its color properties, to the transfer of colorants to adjacent materials, or to both, as a result of exposure to any environment that may be encountered during processing, testing, or storage.

It is defined as a dye, which is a colorant that is applied to or formed on a substrate via the molecularly dispersed state and exhibits some degree of persistence.

AATCC TM163 Color Fastness: Paint Transfer in Warehouse; Fabric to Fabric testing services are also provided.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.