EUROLAB, with its state-of-the-art accredited laboratories and expert team, provides precise and fast testing services within the scope of DIN 53497 testing. In the DIN 53497 standard prepared by the German Standardization Institute (DIN), test methods for determining the hot storage properties of molds made of thermoplastic mold materials without external mechanical stress are defined.

Essentially, this standard includes the following two test methods:

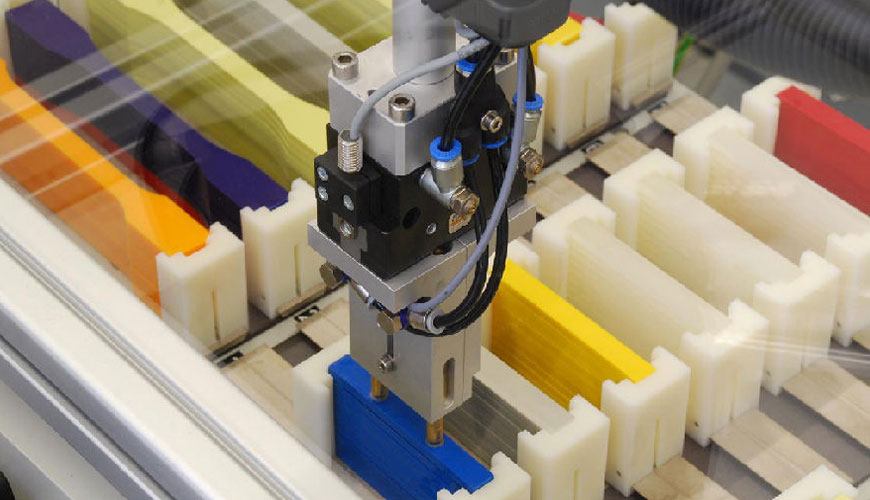

It is often researched what is the best plastic injection molding resin for certain projects. In fact, the best resin is the resin suitable for the operating conditions. You can choose from thousands of plastic injection molding resins with similar but not identical properties. The first thing to consider when choosing a plastic is the function of the material and the physical environment it will be exposed to. Therefore, it is necessary to investigate what kind of injection molding material will withstand various environmental challenges such as temperature fluctuations, humidity, chemical exposure, ultraviolet light and much more. These properties are followed by the strength, durability, flexibility, color and cost of the material. For this reason, tests performed in advanced laboratories are important.

The most commonly used polymers are thermoplastics, namely polyvinyl chloride (PVC), polypropylene and polyethylene. Thermoplastics are a class of polymers that can be softened and melted by the application of heat and can be processed in the thermo-softened state, for example by thermoforming, or in a liquid state, for example, by extrusion and injection molding.

Thermoplastic molding is a reversible molding process in which pellets of plastic are melted, forced into a mold to take its final shape, and then rapidly cooled to harden. Thermoset molding is the reverse process of thermoplastic. Thermoset molding is an irreversible process in which a chemical change occurs in the material rather than a physical one. Thermoset material is injected into a hot mold and then cooled to maintain the final shape of the part.

EUROLAB assists manufacturers with DIN 53497 test compliance. Our test experts, with their professional working mission and principles, provide you, our manufacturers and suppliers, the best service and controlled testing process in our laboratories. Thanks to these services, businesses receive more effective, high-performance and quality testing services and provide safe, fast and uninterrupted service to their customers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.