In the standard developed by the American Society for Testing and Materials (ASTM), these conditions are designed to develop a uniform wear condition called scratch wear. It is applied to determine the relative ranking of various construction materials in an abrasive environment.

The severity of wear in any system depends on the following factors:

The application does not attempt to copy all process conditions such as abrasive size, shape, pressure, impact or abrasive elements. Therefore, it should not be used to estimate the exact resistance of a particular material in a particular environment.

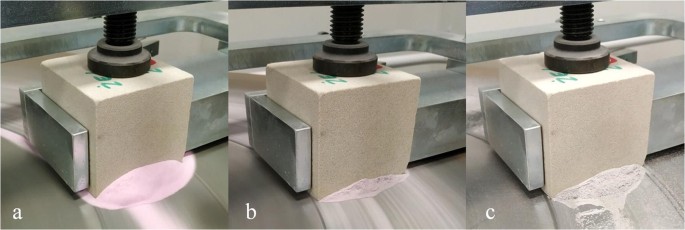

The test method presented in ASTM G65-16e1 includes laboratory procedures for determining the resistance of metallic materials to scratch wear by means of the dry sand / rubber wheel test. The purpose of this test method is to generate data that will reproducibly rank materials according to their resistance to scratch wear under a given set of conditions.

Test results performed are reported as volume loss in cubic millimeters for the given test procedure. Materials with higher wear resistance have lower volume loss.

In order to ensure uniformity among laboratories, it is desirable to report the volume loss due to wear only in cubic millimeters in the metric system.

The test method in the ASTM G65-16e1 standard covers five different procedures suitable for certain abrasion resistance levels or thicknesses of test material:

Procedure A: This is a very serious test that will rank metallic materials on a broad scale of volume loss, from low to extreme wear resistance. Very useful in sorting materials with medium to extreme wear resistance.

Procedure B: This test is a short-term variation of Procedure A. It is used for materials with high resistance to abrasiveness, but is particularly useful in ranking materials with medium and low abrasive resistance.

Procedure C: This test is a short term variation of Procedure A for use on thin coatings.

Procedure D: This test is a lighter load variation of Procedure A and is particularly useful for grading materials with low wear resistance. It is also used to rank certain types of materials that are very close in volume loss rates developed by Procedure A.

Procedure E: This test is a short-term variation of Procedure B, useful for ranking materials with medium or low wear resistance.

Our organization also provides testing services with the ASTM G65 method, within the framework of national and international standards, with its trained and expert staff and advanced technological equipment, among the numerous test, measurement, analysis and evaluation studies it provides for businesses in various sectors.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.