EUROLAB laboratory provides testing and compliance services within the scope of DIN 53380 standard. The DIN 53380 standard serves to determine the rate of passage of gas (eg O2, CO2, N2 and their mixtures) through the plastic film and consequently the suitability of such films for packaging sensitive products, for example. It cannot be used for gases that tend to chemically react with the sample material and condense.

The gas transmission rate is measured by determining the volume of gas passing through the sample under specified conditions, which is suitable for determining gas transmission rates ranging from about 3 cm3/(m².d.bar) to 20 000 cm3. Since the gas transmission rate is dependent on the thickness of the product, reproducible results can only be obtained with samples of equal thickness. For homogeneous materials, the gas transmission rate is generally inversely proportional to the thickness.

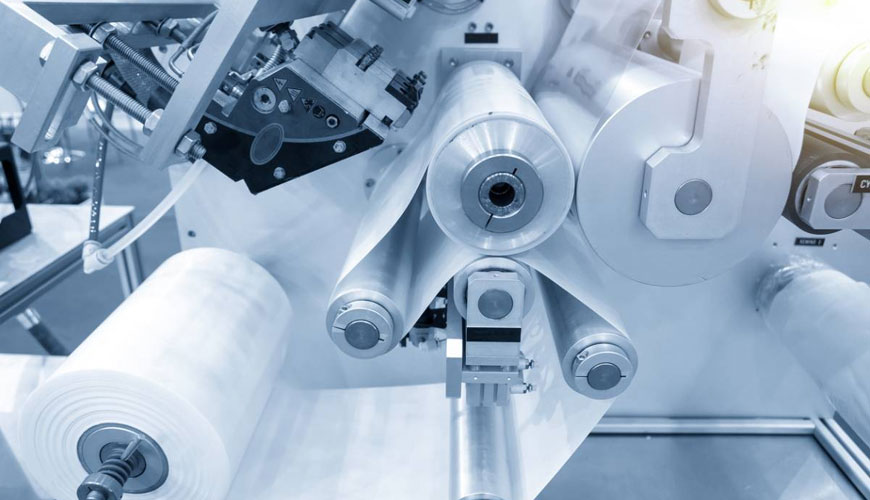

The conduction velocity tester consists of a two-piece stainless steel cell, a measuring capillary with a glass pressure compensation cup tightly coupled to the cell, and a manifold.

The lower part includes a steel plate to receive the circular sample. This plate consists of two areas. To ensure that the gap between the sample bottom surface and the metal surface is large enough to allow the gas passing through the sample to flow into the capillary tube and surround the rough surface, it takes an internal circular area to receive the sample, which is roughened by sandblasting, lubricated during measurement to ensure a smooth floor and gas tightness. consists of a polished circular region.

Samples shall be taken from areas evenly distributed over the surface of the material under test and shall be circular in diameter (approximately 100 mm) depending on the dimensions of the test equipment used. They shall represent the material and shall not contain marks or visible defects (eg holes, wrinkles).

Unless otherwise stated, at least three samples will be tested in one direction. Samples of hygroscopic material must be conditioned before testing at (23 t 2)°C in the chosen atmosphere, the time depends on the material being tested.

Among the services provided by our organization within the framework of material testing services, there are also DIN 53380 standard tests. Do not hesitate to contact our laboratory EUROLAB for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.