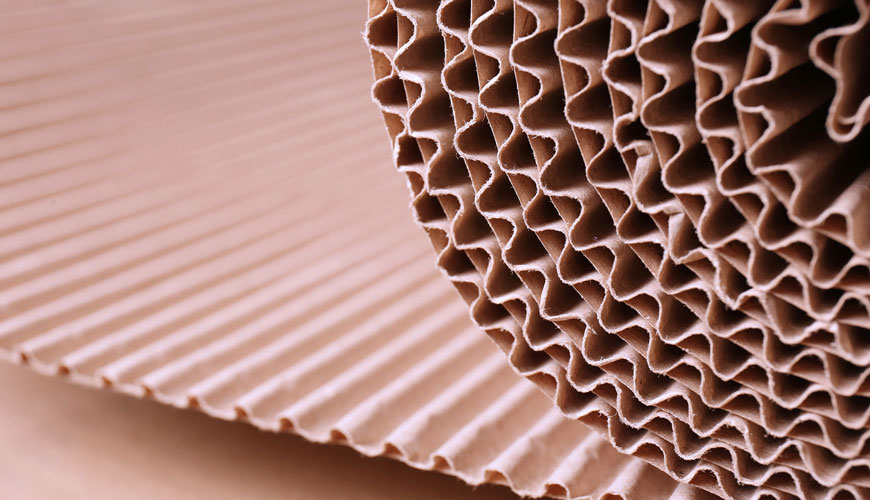

EUROLAB laboratory provides testing and compliance services within the scope of DIN 53122 standard. The DIN 53122 standard serves to determine the water vapor transmission rate (WVTR) of sheet materials by gravimetric method using a wax-sealed container and can be applied, for example, to coated or uncoated plastic film and rubber sheet, paper, cardboard or textile. It is particularly suitable for determining ratios from 1 g/m2d to 200 g/m2d.

Under improved test conditions (eg air pressure control, long test time and constant test atmosphere), the method can also be used down to approx. 0,5 g/m2d.

Concept water vapor, transmission rate For the purposes of this standard, it means the mass of water vapor that passes, under specified conditions, from an evaporation chamber through the exposed surface of a sample to a test vessel per day and per square meter of sample area.

Water vapor transmission rate is not a material constant as it depends on factors including the thickness and matrix of the sample material. Samples with a thickness of more than 3 mm shall be tested as specified in ISO 9932. Above this thickness and above the water vapor transmission rate of 200 g/m2d, the accuracy of the measurement decreases.

A container filled with a principle desiccant is covered with the sample using wax as the sealant and placed in an enclosure with a controlled test atmosphere (for example, a desiccant). The amount of water vapor passing through the test area of the sample surface and absorbed by the dryer is determined by weighing the bowl at regular intervals and recording the increase in mass.

Evaporation chamber with a controlled atmosphere (i.e. temperature relative humidity). The time required to regenerate the atmosphere after the chamber has been closed should be as short as possible and should not exceed 1% of the interval between weighings. If this requirement cannot be met due to the high water vapor transmission rate of the samples, this should be recorded in the test report.

Among the services provided by our organization within the framework of material testing services, there are also DIN 53122 standard tests. Do not hesitate to contact our laboratory EUROLAB for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.