EUROLAB laboratory provides testing and compliance services within the scope of EN 16416 standard. The EN 16416 standard defines an index test method that covers laboratory measurement of water flow through saturated clay geosynthetic barrier (GBR-C) samples using a flexible wall permeability at constant load.

This test method is applicable to GBR-C products that do not have an additional sealing layer added. This test method provides a flux measurement under a predetermined set of conditions that can be used for production quality control.

The test method can also be used to check compliance. The flux value determined using this test method is not considered to be representative of the in-service flux of a GBR-C.

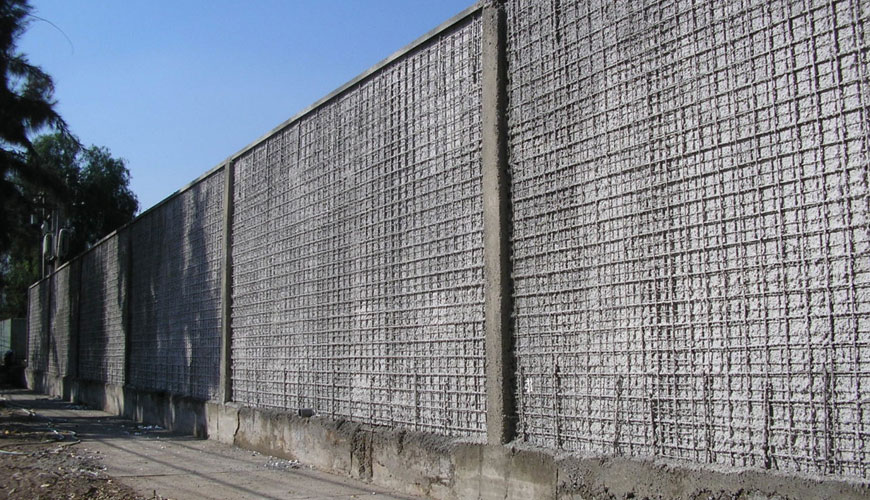

Geosynthetic Clay Barriers: It is a geosynthetic material in which the bentonite layer is placed between two polypropylene geotextiles, one woven and the other non-woven, by mechanical joining.

These layers that make up the GCL are woven together at the production stage to ensure maximum performance and durability. Bentonite and geotextile layers within GCL provide high puncture strength and low permeability values.

Geosynthetic clay cover (GCL) material is produced by bulk needling method after placing bentonite material between woven and nonwoven geotextiles. In general, the upper layer is composed of nonwoven geotextile and the lower layer is composed of woven geotextile. However, in some cases, non-woven geotextiles can be used on both the top and bottom layers. The material produced by this method is also called geocomposite.

Geosynthetic clay cover material is used to provide impermeability. The bentonite material in the middle layer has a high expansion feature when it absorbs moisture, and it reaches the desired impermeability value with the pressure force to be applied on the material during expansion.

EUROLAB, with its more than 25 years of experience, state-of-the-art accredited laboratories and expert team, helps you get precise and fast results. Do not hesitate to contact our laboratory for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.