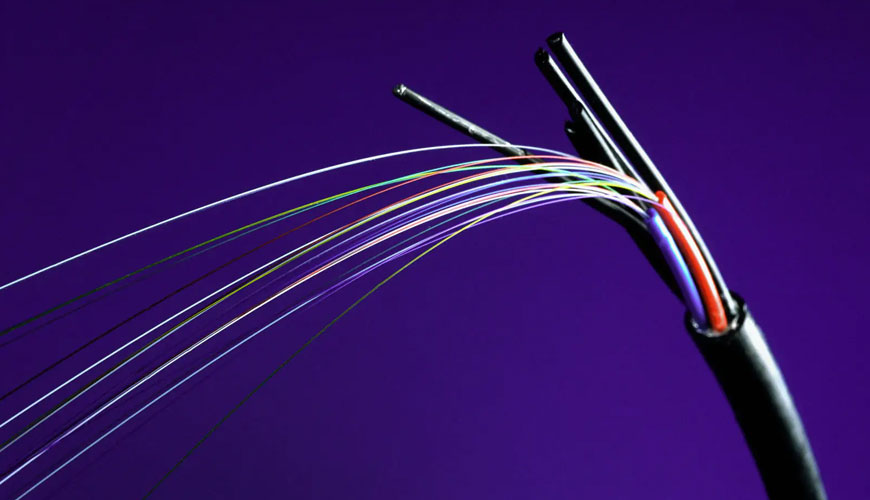

EUROLAB laboratory provides testing and compliance services within the scope of EN 50289-4-17 standard. This part of the EN 50289 standard describes three methods for determining the UV resistance of sheath materials for electrical and fiber optic cables. These tests are valid for outdoor and indoor cable applications according to the product standard. Sheath samples are taken from finished cables. Although this test method is written mainly for communication cables in the European Standard, it can also be used for power cables if called upon by the relevant product standard.

It should be remembered that in the case of a sheath of cross-linked (thermoset) material, the preparation of the molded plates must be done before cross-linking. The methods differ according to the nature of the UV source. Due to the excessive time to failure, the methods described are not suitable for products with UV resistance with ≥ 50290% carbon black meeting the dispersion requirements defined in EN 2-24-2,0.

UV hazard assessment for synthetic compounds is possible using a range of UV sources. For the purposes of this European Standard, three alternative methods are given:

Method A: It uses a xenon arc source to simulate the UV effect on the cable sheath. The effect is measured by the change of mechanical properties after exposure.

Method B: It uses a fluorescent lamp to simulate the UV effect on the cable sheath. Two different lamps can be used; type I (called UV-A lamps) and type II (called UV-B lamps). The effect is measured as in method A, with the change of mechanical properties after exposure.

Method C: It uses a mercury vapor lamp to simulate the UV effect on the cable sheath. As for methods A and B, the effect is determined by the change of mechanical properties after exposure.

For outdoor cable application only, test specimens are periodically subjected to water attack for methods A and B. For Method C, the test is done without water, but results show it is applicable to outdoor environments.

Other sources and determination methods have the ability to detect and analyze the UV hazard for a cable sheath. Examples of such methods are metal halide lamps or sunlight carbon arc lamps with suitable filters to cut off most of the radiation with wavelengths less than 290 nm. Contracting parties may agree to use such other methods, but such methods cannot claim compliance with EN 50289-4-17. If used, it is recommended that such methods have sensitivity and detection levels at least equivalent to those in this European Standard.

The reference source to be used in case of conflict is the arc xenon source as described in method A.

EUROLAB, with its more than 25 years of experience, state-of-the-art accredited laboratories and expert team, helps you get precise and fast results. Do not hesitate to contact our laboratory for your testing and certification requests.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.