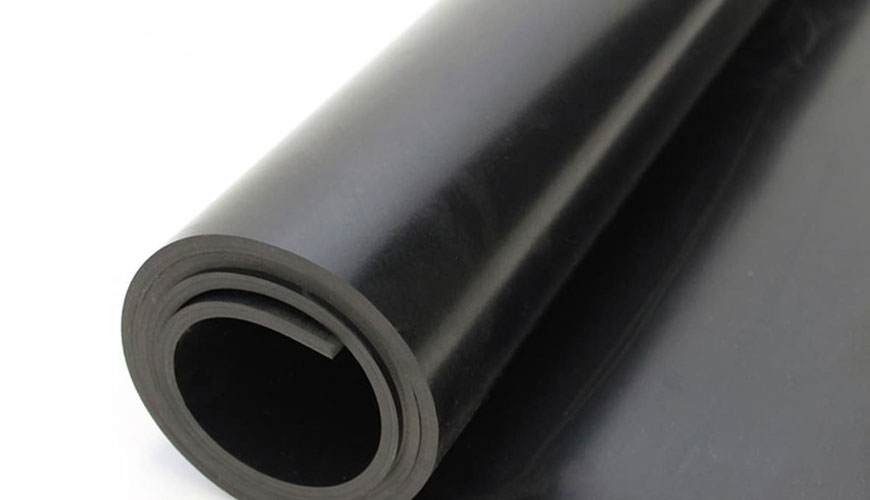

This International Standard describes methods for evaluating the resistance of vulcanized and thermoplastic rubbers to the action of liquids by measuring the properties of rubbers before and after immersion in test liquids. Related fluids include reference test fluids as well as current service fluids such as petroleum derivatives, organic solvents and chemical reagents.

ISO 1817 Standard Simulated Fuels

Commercial fuels vary widely in composition, even within the same class (ie, degree of impact) and from the same source. There are alcohol-based fuels as well as hydrocarbon-based fuels with and without oxygen compounds. The grade of gasoline is improved by adding aromatic or oxygen-containing compounds, but these additives increase the effect of fuels on normally fuel-resistant rubbers.

ISO 1817 Test Scope

The action of a liquid on vulcanized or thermoplastic rubber can generally result in: absorption of the liquid by the rubber, removal of soluble components from the rubber, chemical reaction with the rubber.

The amount of absorption is usually greater than that of extraction, so the net result is an increase in volume, commonly referred to as "swelling". The absorption of liquid can profoundly alter the physical and chemical properties and thus change the tensile strength, extensibility and hardness of the rubber, so it is important to measure these properties after the rubber has been processed. Extraction of soluble components, especially plasticizers and decomposers, can likewise alter the physical properties of rubber and its chemical resistance after drying (assuming the liquid is volatile). Therefore, these properties should be tested after the rubber has been dipped and dried. This International Standard provides methods for determining changes in specifications.

change in mass, volume and dimensions, removable material, change in hardness and tensile stress-strain properties after dipping and dipping and drying.

Although in some ways these tests can simulate terms of service, a direct relationship to service behavior is not implied. Therefore, the rubber that gives the lowest change in volume is not necessarily the best in service. The thickness of the rubber has to be taken into account because the rate of penetration of the liquid is time dependent, and the mass of a very thick rubber product may remain unaffected for the entire projected service life, especially in viscous liquids. It is also known that the effect of a liquid on rubber can be affected by the presence of atmospheric oxygen, especially at high temperatures. However, the tests described in this International Standard can provide valuable information on the suitability of a rubber for use with a particular fluid and constitute a useful check, particularly when used for the development of rubbers that are resistant to oils, fuels or other service fluids.

Test services are provided by EUROLAB to enterprises within the framework of laboratory testing services, within the scope of ISO 1817 Rubber, Vulcanized and Thermoplastic - Effect of Liquids Test Standard.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.